HELMETS FALL OFF...HERE IS A SOLUTION...

HELMETS FALL OFF...HERE IS A SOLUTION...

VIDEO: Helmets Falling Off

www.youtube.com/watch?v=93G27U_HdZY

www.youtube.com/watch?v=93G27U_HdZY

STILLS

According to the official U.S. Army history of wound ballistics from WW2 to Korea [ http://history.amedd.army.mil/booksdocs/wwii/woundblstcs/chapter11.htm]

70, 000 troops were saved by wearing the M1 steel helmet. We lost 368, 000 dead in WW2 so saving 70K is nothing short of a minor miracle. However, retaining the helmet of the head with an adequate 3 or 4 point suspension system seems to have been unfathomable by the U.S. Army that tried to make-do with a single chinstrap and other work-arounds despite the fact that they only had to look at the German Paratrooper's helmet to see an effective 3 point suspension in use. That the current U.S. Army PASGT helmet and the M1 steel pot before it still has the defective single chinstrap 6 decades and thousands of dead later is inexcusable incompetence.

In CHAPTER XII: Wound Ballistics and Body Armor in Korea by Carl M. Herget, Ph. D., Capt. George B. Coe, Ord Corps,and Maj. James C. Beyer, MC [ http://history.amedd.army.mil/booksdocs/wwii/woundblstcs/chapter12.1.htm]

They observe:

"Not all Soldiers wore their helmet, because of its weight, lack of stability, and so forth. Many men on patrols complained about the noise made by the helmet when it came in contact with bushes and twigs and felt also that the helmet interfered with their hearing. For these reasons, some men on patrol preferred not to wear their helmets. These objections to the helmet can be overcome by continuing indoctrination and by improving the helmet characteristics, especially its stability on the head."

So here you have Army medical officers advancing the state of troop body armor as a "preventative medicine measure" and not the infantry whose lives they want to save. What is wrong with this picture? Why are medical officers having to drag the narcissistic egomaniac infantry ahead to save themselves? Do they think they are bullet-proof? Notice helmet design is under the control of the infantry today--Fort Benning---is it a wonder that we still have defective chinstraps on our PASGT helmets? They have no clue how dangerous the Non-Linear Battlefield (NLB) is today when they spend most of their time working on their bodies via sports attire PT so they can pick up chicks and look like what the phony Army/marine bureaucracy thinks they should look like. Image is important to fool the tax payers, substance and performance in combat is not. The people who do know are the Army doctors who try to desperately patch the egomaniacs up and see what happens when even they do reassemble the "Follow Me!" Disciple that the body sometimes refuses to work again. We have the wrong people in charge of troop body armor. If the egomaniac infantry is not interested in saving themselves from a flag-draped coffin ending, then Army Medical Branch should be placed in charge of body armor design and development as should Army engineers should be in charge of armored vehicle design since they know what high explosives can do on the NLB.

Furthermore, this BS of doing half-assed field training not wearing body armor and ammunition loads which distorts our Soldier's load planning and field living skills development to learn how to live lighter in the field with less equipment must end forever. This trash talk that we will "train as we fight" must stop and the actual deeds done. The way to do this is by ending our "Beetle Bailey" garrison mindset and fixation with static buildings and lawn care by completely ISO containerizing ourselves and everything we own and operate into "BattleBoxes" that are in the field every day on every Army post so every day we dress for war to include full body armor, ammunition loads and weaponry.

The following article by Army and marine enlistedman and officer Mike Sparks begins at today's PASGT "kevlar" helmet which replaced the M1 steel "pot" helmet but kept the pathetic single chinstrap.

Wednesday, November 15, 1995 with 2005 UPDATE!

THE FORT BRAGG POST

Another Paratrooper is dead after a "routine" parachute jump, possibly after his PASGT kevlar(r) helmet became unsecured. Last year, it was a sub-120 pound jumper getting towed: she died when her helmet too, fell of as she banged against the plane. Light jumpers should be at the end of the stick so they can be discovered/pulled in by the jumpmaster if towed. A new DA Form 1306 Aircraft Loading manifest with blocks to fill in the Soldier's height/weight and number of jumps, special equipment would increase jumpmaster situational awareness and insure lighter Paratroopers jump last in their sticks. If we had a streamlined T-21 parachute with the reserve at the back with the main, we wouldn't have some much clutter causing Paratroopers to get snagged upon exits out narrow jump doors like the C-130 has. Even if you adjust the helmet "by-the-book" the current chinstrap is notorious for popping loose at the "pull-the-dot" metal snap and sags low over your eyes regardless when low-crawling.

SOLUTION #1: THE GENTEX 3-POINT SUSPENSION CHINSTRAP

GENTEX CO.

POB 315

Carbondale, PA 18407

(717) 282-8555

To prevent further head injuries, what we need now is a Fastex(r)-buckle 3 or 4-point suspension chinstrap for the PASGT Kevlar(r) helmet, which will keep the helmet securely on in an effort to save your life from impact. The current metal "pull-the-dot" snap corrodes, bends and is notoriously unreliable.

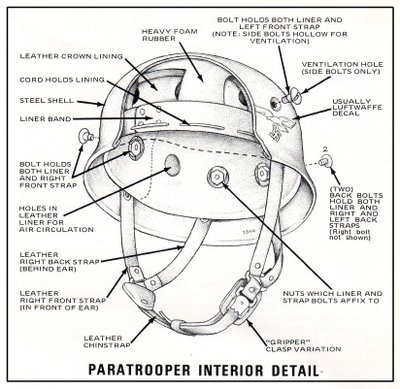

Click on Picture for details

http://germanmilitariacollectibles.com/blog/2008_11_01_archive.html The Fallschirmjager Helmethttp://germanmilitariacollectibles.com/blog/uploaded_images/Img4-736354.jpg

Fallschirmjager in German is actually three words. They mean, "fall, umbrella and hunter". Combine it and you have a "fighter from the skies".

The Fallschirmjageror Paratrooper wore a different uniform and insignia than the regular ground troops. His helmet also was one of unusual design. It is apparent that it was copied from the standard M35 helmet with the probability of having parts omitted. The visor and earguards were removed to enable the headgear to be more compact and thus avoiding much of the protrusive parts in air maneuvering.

The necessity of a different strap assembly was provided to prevent the loss of the helmet in the air and also giving more safety to the chin and neck regions from jolts and pressures. This is known as a "chin harness". There were four variations:

1. Early issue was grey leather, backed by chamois on the side that touched the face. It had a quick release buckle of two positions with snaps.

2. A wider but thinner material, grey leather with ersatz (fake) chamois backing and a standard slide buckle.

3. Late issue, very hard leather and instead of the slide straps being sewn, they were riveted on. The harness was much thicker than the first two.

4. Remade harness: After the Paratroopers were taken off jump status and used as infantrymen for the duration of the war their helmets were refitted with a D-ring and a standard buckle as the standard German army helmet. These were not as heavy or bulky as the jump issue.

For shock more padding was necessary and special allowances were used in the dome with the support of a rubber lining that ran almost the extent of the interior. This was covered with a leather lining and contained twelve holes for ventilation. The helmets were issued in the following metric sizes; 54, 55,56, 57, 58, 59, 60, 61.

Instead of the regular type rivets for securing the liner to the shell, a bolt and nut system was used. This again was for prevention of breakage that could occur in the air. Some examples are known, and some "raw edges" were produced, but otherwise all paratrooper helmets had a "rolled edge". Paratrooper helmets had the silver Luftwaffe insignia on the left side (few examples were produced at the beginning of the war with Wehrmacht insignia) and national colors on the right.

Helmet Covers

1. Cloth helmet cover, blue grey with slots for camouflaging. These were first used on Crete.

2. Two different patterns of camouflage coversbeing a early issue and late issue. These were the same type as the camoflage smocks(jump suit) held on by clips with slots etc.

3. Chicken wire cover. These were of heavier steel than normal chicken wire. They were sized to the helmet and held on by two clips, one on each side.

4. Net type cover. Large holes in the netting. Liner was removed then net put over the helmet and liner replaced.

5. Mud Covering. Helmets were covered with mud and allowed to dry. This gave the blue-grey helmet more of an earth color.

The 2nd Fallschirmjager Division that saw service in North Africa, used the standard paratrooper helmet with Luftwaffe decal-insignia. All were painted an Africa Korps tan, by the parachute riggers and personal equipment men of each Regt. They brushed on two or three coats of standard paint that was used on trucks etc. In doing this they covered up the flying eagle insignia. The paint jobs ran from excellent to poor, depending on how rushed they were and the craft-ability of the artist.

Floyd R. Tubbs, Stahlhelm, Evolution of the German Steel Helmet, Author Published, 1971

The Gentex Fastex(r) chinstrap has been on my helmet for more than a year. The strap comes in small, medium and large. It was jump tested at LeapFest '95 in August and has been checked out by the 1st Brigade of the 82nd Airborne Division. I haven't written about it because I was going to let Natick Labs work through their certification process, but now another Paratrooper is dead. We are supposed to get a decent chinstrap with the 21st Century Land Warrior program (21st CLAW), but how many will have to die or be seriously injured before these arrive?

Before one more Paratrooper dies needlessly, slandering the viability of the Airborne operation, we need these chinstraps on all 82nd Airborne Division Paratrooper helmets on an emergency interim basis without waiting for the bureaucratic "process" to kick in. Not only will the Fastex(r) quick-release buckle save lives, it will be dramatically more comfortable and keep helmets from sagging over eyes when low crawling.

Ask the Australian Airborne, which uses the Kevlar(r) helmets with the Fastex chinstrap. Australian SAS members now in the desert report to us that these helmet's buckles will give way in the event of a nearby explosion, saving injuries from necks being snapped. If we cannot buy these, then local Riggers could sew a strip of material with a Fastex(r) buckle on top of the metal snap of the current chinstrap to make it doubly secure. It has been several years since the then 82nd Airborne Division commander lost his helmet on a jump and subsequently ordered a fix. So much for "you have to be a General to get anything done". RIGHT. The bureaucracy is so corrupt, even generalks cannot force things to be fixed. Is this brain surgery?

The courageous Paratroopers of our Airborne have waited long enough.

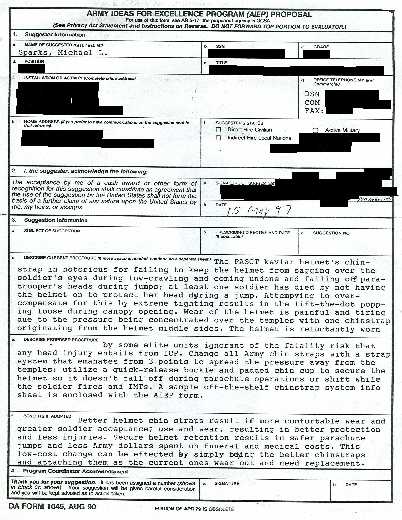

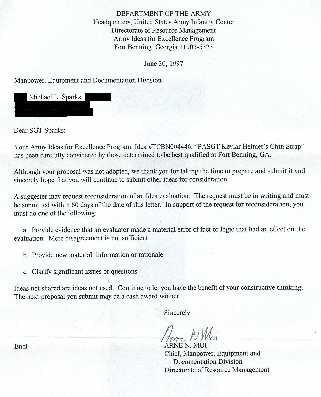

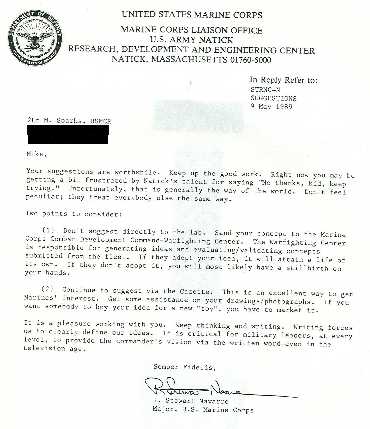

So in 1997, 1st Tactical Studies Group (Airborne) Director, Mike Sparks makes the suggestion for a better chinstrap through the Fort Benning Infantry Center/School Army Ideas for Excellence [whitewash] Program (AIEP) program.

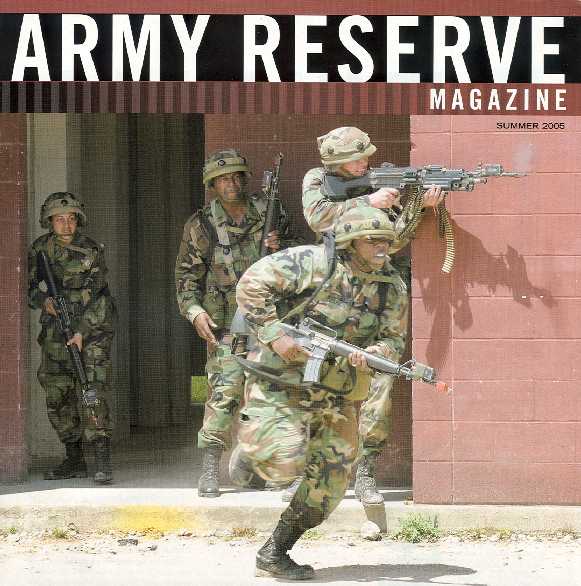

Now notice in the picture on the top of this web page of a Soldier in 2005 running wearing the PASGT helmet without even the Paratrooper's retention strap--a mere two point suspension---its sagged over his eyes and he cannot see where he is going.

This obvious defect of the PASGT helmet was pointed out by Sparks in 1997. So the need for a better chinstrap is an urgent concern FOR ALL THE U.S. ARMY.

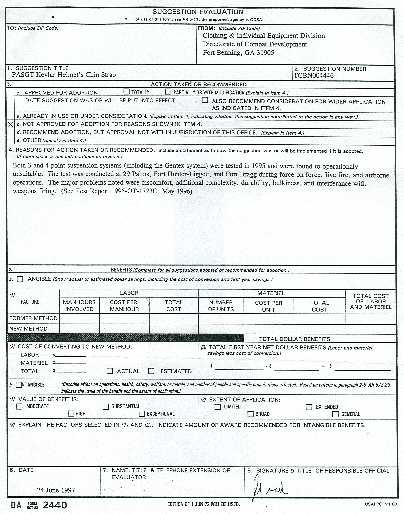

Yet read the absurd bullshit response from the Army on how 3 and 4 point suspensions don't work--as if the 2 and 3 point PASGT helmet chinstrap and suspensions do:

After reading the Army's pile of bullshit (BS), consider that since then thousands of Soldiers have worn the MICH/ACH helmet with its 4-point suspension and not had them fall off during parachute jumps--nor droop down over their eyes during combat, saving many lives and preventing injuries. Then consider how if we interviewed all these Soldiers and asked them to compare their MICH/ACH helmets to the old PASGT helmet chinstraps they'd no doubt say the old helmets sucked. The Army bureaucrat filling out the AEIP paperwork is out-of-touch-with-reality in his lust to make excuses for the status quo to ingratiate himself with the bureaucracy. Americans have no concept of excellence which requires CONTINUOUS IMPROVEMENT--not sitting on the status quo.

Below is an Army RDECOM magazine article singing the praises of a 4-point chinstrap suspension system and why its superior to the existing PASGT 2-point suspension system. "Natick, we have a problem"---Fort Benning says there is no problem with the PASGT chinstrap even though the helmet is sagging over their eyes and they can't see anything, maybe that's a condition they are used to? Here's an excerpt:

"By incorporating a four-point retention strap, similar to the MICH, the lightweight helmet is seven times more stable than the Kevlar, so it won't rock back and forth or fall off. Although most marines won't be jumping out of airplanes, it's airborne-certified."

www.rdecom.army.mil/rdemagazine/200309/itf_marines_lw_helmet.html

RDECOM Magazine | in the field |marines Field Lightweight Helmet

Natick Soldier CenterFielding of more than 200,000 of the lightweight helmets to marines will start this summer, replacing the old "Kevlar," as it's commonly called, which has been around since the early 1980s.

Natick, Mass.-It may not look much different from the current Personnel Armor System, Ground Troops helmet, but the new marine Corps Lightweight Helmet is improved in almost every way. Fielding of more than 200,000 of the lightweight helmets to marines will start this summer, replacing the old "Kevlar" as it's commonly called, which has been around since the early 1980s.

A project that began in 1999, the helmet is part of the redesign of all individual equipment for marines, according to Jim Mackiewicz, marine corps customer team leader at the Soldier Systems Center. The team provides technical and contract support for Product Manager-Individual Combat Equipment at the marine corps systems command in Quantico, Va.

Helmet prototypes went through operational testing at the marine corps Air Ground Combat Center in Twentynine Palms, Calif., in 2000 and 2002 during combined arms field exercises. In addition, the helmets were field-evaluated by marines at Camp Lejeune, N.C.

"It was one of the highest rated pieces of equipment in the (marine corps Operational Test and Evaluation Activity)," Mackiewicz said, who was project officer for the helmet. "To get an 85 to 90 percent approval rating is almost unheard of."

Marines can look forward to improved comfort with the new lightweight helmet, which features soft black leather for the X-shaped nape pad, headband and border around a new breathable nylon mesh suspension pad, and black suede-lined chinstrap. Two buckles on each side of the helmet provide tensioning and centering of the nylon retention webbing.

Testing lasted an extra year to work out glitches and allow time to compare the Army's new Modular Integrated Communication Helmet, or MICH, he said.

"Both the lightweight helmet and the MICH were comfortable and higher rated than the (marine's previous helmet), but the lightweight helmet was higher rated than the (older version)," said Maj. Stuart Muladore, Product Manager-Individual Combat Equipment team leader. "As it boiled down, it was still the helmet of choice for us."

The helmet's shell is shaped like the older version, but new materials bring a 6 percent improvement in fragmentation protection, as well as the ability to stop a direct hit from a 9mm round. Lab testing showed a 40 percent improvement in impact protection, which also means better durability. The manufacturer, Gentex Corp. in Carbondale, Penn., warrants the helmet for 15 years.

As the helmet's name suggests, the extra capability was designed with a corresponding weight reduction of about one-half pound. For comparison, a medium-size older version helmet weighs 3.6 pounds versus a medium lightweight helmet's 3.05 pounds.

"It's the same weight as the MICH but doesn't lose the area of coverage," Mackiewicz said. "We could have made it as light as 2.8 pounds with a MICH-style cut. The MICH feels good, but marines said they didn't feel as protected wearing it."

Complaints have been voiced about the Kevlar interfering with the Interceptor Body Armor, but the solution was more a matter of improving stability, not just reducing size, he said. By incorporating a four-point retention strap, similar to the MICH, the lightweight helmet is seven times more stable than the Kevlar, so it won't rock back and forth or fall off. Although most marines won't be jumping out of airplanes, it's airborne-certified.

Comfort is improved with soft black leather for the X-shaped nape pad, headband and border around a new breathable nylon mesh suspension pad, and black suede-lined chinstrap. Two buckles on each side of the helmet provide tensioning and centering of the nylon retention webbing. The Kevlar helmet's five sizes remain, but marines can easily adjust headband circumference and height by one-half inch with the lightweight helmet's hook and loop fabric fasteners for a better fit.

"One reason we didn't go with a trimmed version is because you can have it sit too high," he said.

Both adjustments help accommodate marines when they're wearing masks or hoods, or when any helmet-mounted displays or optics are attached. Heat stress is similar to the Kevlar, according to Mackiewicz, and in anticipation of wear and tear, each helmet is delivered with a replacement kit containing an extra chinstrap and two headbands.

So how in the hell does the Army's bureaucrats get off saying such lying bullshit back in 1997 WHEN THERE WAS A PROBLEM?

We KNOW THERE WAS A PROBLEM WITH THE CHINSTRAP BECAUSE SPARKS AND OTHERS EXPERIENCED IT FOR YEARS. WHY DID IT TAKE THE FUCKING SPECIAL FORCES TO BREAK RANKS WITH THE REST OF THE ARMY AND INSIST ON A HELMET AND CHINSTRAP THAT WORKS---FOR THE REST OF THE ARMY TO UNFUCK ITSELF?

Why all of a "sudden" the chinstrap was a problem when "special" troops complained? So the laws of physics don't apply when a non-special feces Soldier has a helmet fall off? Its somehow his fault(?) because he's viewed by the narcissistic bureaucracy and blue-collar rank & file as a "lesser being"?

No, the problem is with Fort Benning; a BUREAUCRACY of non-professional lemmings populated by some snobby Airborne/Light Infantry/Ranger assholes who think their shit doesn't stink. Like marines--but not without some justification--jumping out of airplanes at 500 feet at 150 miles per hour with 50+ pounds of equipment in the dead of the night does indeed take far more courage than a gyrene sitting his ass on a helicopter bench seat and being gently landed into an open danger area packed like sardines with other men in a bloated tin can full of fuel. However, let's not have this go to our heads and create a BS "Blood on the Risers" culture of bragging victim-mongering by deliberately not improving the Airborne operation. All they had to do is get off their fat asses and step out of their building 4 office space and look at the jump tower training for a few minutes and see old PASGT helmets flying off as students stepped off the 40 foot tower. But it's obvious narcissistic egomaniacs do not give a damn about the troops unless the commanding general orders them to act like decent human beings. They have no moral compass of their own. Its all a stupid macho game of "penis size" to them. This is why Airborne school is so fucked up--and its safety situation is getting worse as the narcissism that resists problem admission & solution increases. "Airborne" to them is a big ego trip [when it should be about 3D maneuver to win wars]. For example, when a female student recently died it was somehow HER FAULT THEY SAY for not pulling the reserve ripcord when her main parachute didn't open; when the TRUTH IS THAT ITS AIRBORNE SCHOOL'S FAULT FOR NOT DRILLING HER AGAIN AND AGAIN AND AGAIN--RIP-CORD PULLS WHILE IN SUSPENDED HARNESS TRAINING--SO IN A LIFE/DEATH JUMP SITUATION PULLING THE RIPCORD WOULD BE A PART OF HER MUSCLE MEMORY--LIKE THEY DO IN CIVILIAN SKYDIVE TRAINING. Always blame it on "pilot, ehh jumper error" the dead guy or gal who is not there to defend himself. Really despicable bureaucracy corruption crap. Defend the fucked up and corrupt bureaucracy at ALL COSTS. Fort Benning's "blood on the risers" jump school killed her. Just like they are killing the Airborne operation and the 3D maneuver America needs by their fucked-up view that its only an I'm better-than-you "hooah" badge.

SOLUTION #2 IMPLEMENTED: IN 2003--THE U.S. ARMY HAS ADOPTED THE NEW MICH HELMET CHINSTRAP!

MICH helmet and chinstrap for SF

The Army has a new 4-point chinstrap being developed for its SF MICH helmet that needs to be immediately put on ALL Paratroopers on jump status NOW. We had a Soldier die last year when his helmet fell off--who would be alive today---if he had this new chinstrap.

Saying we have to wait for all our chinstraps to wear out is MURDER. This is like saying you have cars with defective breaks and not changing them until they wear out or a fatal accident takes place. An ounce of PREVENTION is better than a pound of "cure" too late.

The new chinstrap's National Stock Number (NSN) is 5895-01-476-2605 (Medium/Large) but you need to specify the chinstrap has a single rear attachment point for it to interface with the existing holes on the PASGT kevlar helmet. The MICH helmet strap for the PASGT helmet is connected at 3 points, thus it requires no drilling or new bolt/nut hardware. Manufacturer is CGF Helmets.

Cost is $13.

Illustrated power point presentation of how to install MICH chinstrap to PASGT helmet

www.reocities.com/michhelmetstraps

General instructions:

1. Cut off the center tab of the rear shock pad

2. Remove camouflage cover, existing chinstrap, return nut/bolt to cover holes up.

3. Remove front side suspension bolts, add MICH chinstrap buckles and re-assemble.

4. Remove rear suspension bolt, attach MICH "V" shape attachment hole, suspension nylon and shock pad, tighten bolt/nut.

523 Benfield Rd.

Severna Park, MD 21146

Phone # 410-647-8833

Fax # 410-647-8828

Another nagging problem with the current chinstrap is that during low-crawl and other individual movement techniques (IMT) the brow the helmet will dip down blinding the Soldier at a critical time when he needs to see the enemy and shoot his weapon to kill-him-before-he-gets-you. The kevlar helmet dipping down is attributed to at least 2 fatal military motor vehicle accidents. The MICH-type chinstrap will solve this problem forever.

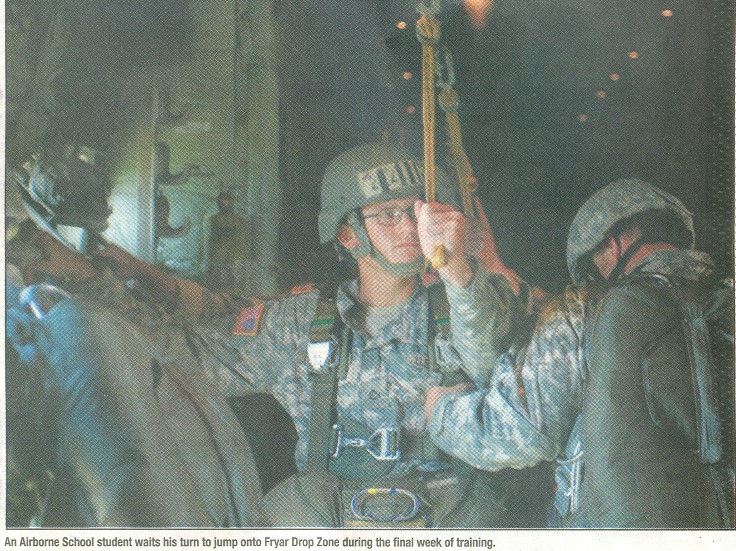

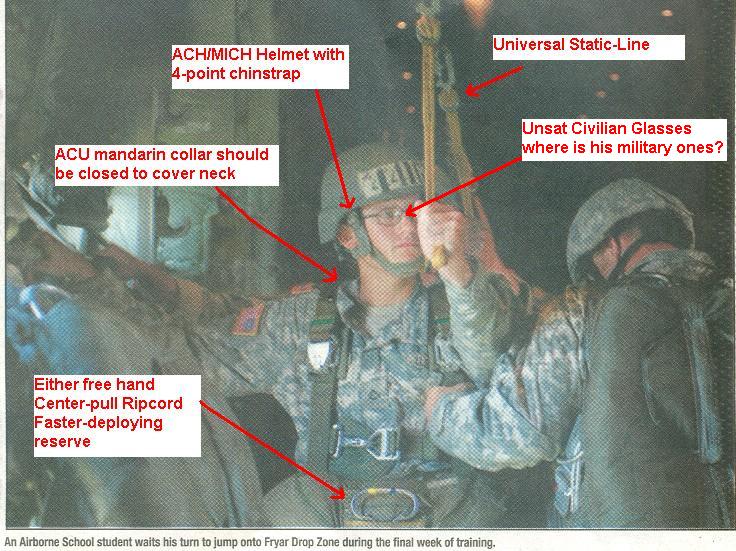

SOLUTION #2 IN ACTION TODAY AT U.S. ARMY AIRBORNE SCHOOL DECADES LATE

How many have died and been damaged for life needlessly because snobby more-Airborne-than-thou types denied there was a problem with the PASGT chinstrap?

CLOSER EXAMINATION: PROGRESS BUT STILL FLAWED PRACTICES

Fort Benning BAYONET photo by Captain Kamil Sztalkoper

PROBLEM #2: THE SUSPENSION AND LACK OF IMPACT PADDING

The dirty secret of the PASGT helmet is that its painful to wear because the current headband suspension system:

The "New" slightly improved U.S. Army issue helmet suspension is as follows:

Improved PASGT helmet Suspension

NSN 8470-01-442-2969 (sx)

-2990 (s)

-2995 (m)

-3001 (l)

-3021 (xl)

Improved Headband, PASGT Helmet

NSN 8470-01-442-1429 (s-m-l)

While the headband has velcro instead of metal clips to attach a wider headband, the fact remains that the PASGT helmet is still painful to wear resulting in lax Soldiers and particularly marines not to wear them, even in a combat zone like Afghanistan! If you are not wearing your helmet your head can be easily injured and your life ended by mundane bumps working around heavy equipment as well as enemy fire. The problem with the PASGT helmet is NOT its weight (3 pounds) but HOW ITS SUSPENDED ON THE SOLDIER'S HEAD.

In a more physical age, Americans better understood the need to physically spread loads to cushion impacts. For example, the WWI "pie plate helmet" is actually more comfortable to wear than the WWII "steel pot" helmet because it has a wider headband.

However, widening the headband does not stop the helmet from smashing against the skull after a hard impact from a parachute landing fall or vehicle accident. This is why motorcycle and bike helmets have surrounded the entire head with shock absorbing material so the inside wall of the helmet does not smash against the skull and injure it with concussion and collapse. Every U.S. Army Soldier is supposed to be wearing a kevlar PASGT or CVC helmet when operating tactical vehicles in peace or in war. Motor vehicle accidents are the number #1 cause of Soldier/marine deaths each year. If we were to properly cushion and suspend every PASGT helmet in the U.S. Army and marines we would save thousands of lives and millions of dollars.

Some have proposed throwing out the millions of PASGT helmets we have and replace them with $350 each MICH helmets (the start-over approach) which have Oregon Aero impact resistant padding and more comfortable, safe suspension.

Oregon Aero has three kits to fix this:

KLU: Fix the headband

The KLU(tm) G.I. Soldier Helmet Upgrade works with existing webbing without helmet modification and basically widens the helmet band and gives impact resistant padding.

Oregon Aero's KLU(tm) G.I. Soldier Helmet Upgrade is installed in less than 5 minutes and offers the G.I. a pain-free kevlar helmet (KLU stands for "Kevlar Liner Upgrade"). In the words of the National Guard Command Sergeant Major responsible for the helmet's first evaluation;

"The KLU(tm) G.I. Soldier Helmet Upgrade is ...a godsend to the infantry Soldier, likely the greatest invention since the P-38 can opener."

Either the Army or individual G.I.'s can purchase and install the KLU(tm) G.I. Soldier Helmet Upgrade kit. The upgrade kit works with existing helmet webbing without any helmet modification.

The one-size-fits-all KLU(tm) G.I. Soldier Helmet Upgrade is made from a patent-pending proprietary composite construction. It features improved wicking properties and shock absorption and can be machine-washed and air-dried. Oregon Aero has built a specially adapted, semi-automatic, template sewing machine to manufacture the BLU(tm) and KLU(tm) Helmet Upgrade.

BLU "Ballistic Liner Upgrade": Replace the suspension

The upgrade kit can be installed in any style ballistic helmet. Soldiers can train and perform missions with a pain-free, stable, safer helmet, thanks to Oregon Aero's BLU(tm) Soldier Helmet Upgrade Kit. Branches of the U.S. military commissioned Oregon Aero to create a helmet upgrade because of Soldiers' chronic complaints that helmets were painful, uncomfortable and unstable. The modified helmet works equally well with or without external equipment such as night vision goggles, which require a high degree of helmet stability to work properly. Military tests performed on the custom designed Helmet Upgrade revealed dramatic improvements in levels of transmitted shock loads, improving the helmet's safety. Transmitted shock loads decreased from an average of 300G's to an average of 75G's with the BLU(tm) Soldier Helmet Upgrade. (300G's is the threshold between concussion and fatality, and 75G's is below the threshold of injury, which is around 90G's).

The Upgrade wicks heat and perspiration away from the scalp, reducing heat buildup and the problem of perspiration rolling into the user's eyes. The BLU(tm) Soldier Helmet Upgrade can be machine washed and air-dried.

A patent is pending for the helmet upgrade's proprietary, composite design.

BLSS (Ballistic Liner Suspension System): Replace the chinstrap, do away with the headband and suspension

The BLSS(tm) Kit is stable, pain-free, safer, waterproof, self-wicking, positively buoyant, air permeable, reduces sound reverberation and is installed without any helmet shell modifications. The Kit includes a four-point chinstrap connected to a lateral band/harness which mounts to existing PASGT helmet holes/bolts. It has an integrated nape pad and seven highly engineered impact pads that replace the PASGT parachute impact helmet liner (PIL). The camouflage helmet cover connects to the lateral band.

Here was the challenge for Oregon Aero from the U.S. military:

Using the military's existing PASGT helmet, create a stable helmet, one that remained solidly on a Soldier's head regardless of what the Soldier is doing. The military also asked that the current chinstrap be replaced with something more effective and that the upgrade be able to be installed without any helmet modifications.

The military got what it wanted-and more. The new Oregon Aero Ballistic Liner Suspension System (BLSS(tm) Kit):

Is always STABLE, (it uses a highly engineered pad system instead of a web system).

Is PAIN-FREE (the visco-elastic, temperature and pressure sensitive padding system removes all pressure points).

Is SAFER (shock transmission is reduced from 220Gs to 77Gs with top impact and from 161Gs to 88Gs with side impact).

Is WATERPROOF (a proprietary coating application developed by Oregon Aero allows submersion to 66' and passes other requirements).

Is AIR PERMEABLE (the same proprietary coating application permits air, but not water, to pass through).

REDUCES HELMET SOUND REVERBERATION (auditory sense of the surrounding environment is improved).

Is SELF-WICKING (the helmet's cooler: heat and perspiration are drawn away from the scalp and evaporate).

Is POSITIVELY BUOYANT (so the helmet is safer in amphibious or water fording situations).

REQUIRES NO HELMET MODIFICATION (the entire system uses the same six bolts and plates of the current issue web system).

The Oregon Aero BLSS(tm) Kit is being evaluated in military field tests.

The helmet upgrade's breakthrough chin retention system includes a four-point chin strap/harness with an integrated nape pad. The liner upgrade includes seven individually designed and manufactured pads. These, two-part, visco-elastic foam pads are pressure and temperature sensitive and provide pain-free use, no matter how long the helmet is worn. The pads also enable the helmet to remain stable, even when the user is in a prone shooting position. Each pad goes through 27 manufacturing steps.

The padding system, developed by Oregon Aero as the Ballistic Liner Upgrade (BLU(tm) Kit), also is used in the military's Modular Integrated Communications Helmet (MICH).

2005 CONCLUSION

THOUSANDS OF SOLDIERS are still stuck wearing the PASGT helmet with the absurd and unsafe 2-point chinstrap suspension. HOW MANY MORE WILL HAVE TO DIE? At the very least for god's sake order parachute retention straps for your men and have them wear them for at least some better stability. So fucking what that you are "not Paratroopers". FUCK THAT. Do you want the helmet drooping over your eyes? Wake-the-fuck-up. Stop being a lemming victim in the Army's weak co-dependence paradise (nightmare). Stand up for yourself so you get the job done and come home alive. Act like a man--not a mouse.

The more frugal and wise option to GET ALL SOLDIERS A BETTER CHINSTRAP/SUSPENSION would be to simply retrofit Oregon Aero suspension and impact padding into every U.S. Army PASGT helmet with the MICH chinstrap (3 or 4 points) at a cost of about $100 each as the U.S. Army National Guard Light Infantry Brigades are doing:

www.oregonaero.com/p81_2001.html

Oregon Aero, Inc.

34020 Skyway Drive

Scappoose, Oregon 97056

(503) 543-7399 Fax -7199 1 (800) 888-6910

Also notice in order for special feces troops not to look like the "unwasheds" they wanted the MICH helmet to LOOK DIFFERENT so they reduced the size of the helmet under the "Fritz" ear overhang to ostensibly enable them to better lift their heads up in the prone. At least one Army surgeon has gone on record as saying the reduced ballistic coverage of the MICH/ACH helmet has caused the head wounds (see article on bottom of this web page) and deaths of some Soldiers in Iraq. Notice, however that if the 1st TSG (A) suggestion of retrofitting better chinstraps/suspensions had been done to ALL PASGT helmets as we proposed in 1997 and even as late as 2003, these Soldiers would be alive today. Chalk up another FUBAR to the stodgy Army bureaucracy and uncaring brass.

So, "YES" we in the 1st TSG (A) "told you so".

Not only that, WE WILL KEEP ON TELLING YOU AND ANYONE ELSE WHO GIVES A DAMN ABOUT OUR SOLDIERS AND DEFENDING FREEDOM "SO".

One last thing. Notice once we went to quasi-war after 9/11/2001, "ALL OF A SUDDEN" people realized that the PASGT helmet chinstrap and suspension stunk. WHY DIDN'T THEY NOTICE THIS BEFORE LIKE WE DID? WHAT WERE THEY DOING ALL THE YEARS PRIOR TO THAT? WERE THEY GOING TO THE FIELD?

NO.

They were spending the day mowing lawns, polishing floors, and doing silly sports PT WHEN THEY SHOULD HAVE BEEN DRESSED FOR WAR EVERY GODDAM DUTY DAY.

And don't doubt for one second, when the misguided occupation of Iraq is over, the weaklings will rip off all the armament, armor they can to return to the bullshit garrison lifestyle/routine A-S-A-P.

We think America should NOT be funded welfare recipients-in-uniform to spend half the day doing jogging and the other half as lawn care specialists. We should fire ALL those in the army/marines that support such bullshit and GET RID OF ALL THE FANCY BUILDINGS AND LAWNS they use to justify their wasting the day to be fucked up and not combat-ready. Here is how to do it:

Until we realize how dangerous the Non-Linear Battlefield (NLB) of today is, and START SPENDING EVERY WAKING MOMENT ON COMBAT SKILLS AND CAPABILITIES, we are going to continue to get our asses kicked by teenagers with a finger on the button to set off a command-detonated landmine A.K.A. a ROADSIDE BOMB. We do not call CDLMs "IEwhatevers" that's a bureaucratic cop-out to pretend these are "new" threats to cover the asses of the incompetents who should have been studying their profession and watching event is places like south Lebanon where Hezbollah used these weapons against the IDF. Maybe if we spent less time being snobs, wasting time in the gym and being lawn mowers we'd know more about what to do to win wars?

BACKGROUND

1. The History of WW1 and WW2 Helmets and body armor in general

Official U.S. Army history of wound ballistics from WW2 to Korea

http://history.amedd.army.mil/booksdocs/wwii/woundblstcs/chapter11.htm

CHAPTER XIPersonnel Protective Armor

Maj. James C. Beyer, MC, William F. Enos, M.D., and Col. Robert H. Holmes, MC

The development and field usage of helmets and body armor in warfare before World War II has been adequately documented by a number of excellent books and reports.1 Most of these references have been utilized in the preparation of this chapter, and in many instances they have provided the sole source of available material.2

HELMET DEVELOPMENT

During modern times, the helmet has had a rapid rise in general troop acceptability with remarkably little variation in design. The first protection provided for the head in World War I came about in a purely fortuitous manner. General Adrian of the French Army noted that a Soldier who had received a head wound due to a rifle bullet explained his escape from death on the fact that he had carried his metal food bowl under his cloth cap. Therefore, following initial experiments in 1914, steel cap liners ("casque Adrian") were issued to French troops in 1915 and led to the characteristic World War I French helmet in 1916. Many of the other countries soon realized the value of a helmet. The British adopted their own design in 1915; the Germans, in 1915; and the Belgians and Italians, in 1916.

1(1) Helmets and Body Armor. Handbook of Ordnance compiled by H. T. Wade. Washington: Government Printing Office, 1919, pp. 413-418. (2) Dean, Bashford: Helmets and Body Armor in Modern Warfare. New Haven: Yale University Press, 1920. (3) Dean, Bashford: Helmets and Body Armor-The Medical Viewpoint. In Medical Department of the United States Army in the World War. Surgery. Washington: Government Printing Office, 1925, vol. XI, pp. 1-8. (4) Helmets and Body Armor, Office of the Chief of Ordnance, Washington, 1 June 1945. (5) Gregg, Anne J.: Project Supporting Paper No. 44 Relating to Helmets and Body Armor, 1917-August 1945, Ordnance Department, Washington, D.C. (6) Peterson, H. L.: Body Armor in Civil War. Ordnance 34: 432-433, May-June 1950, (7) Ward, Gordon B.: Personnel Anti-Fragmentation Equipment. Library of Congress, Technical Information Division, Washington, D.C., July 1955. A bibliography, 63 pages.2 The members of the Historical Division, Office of the Chief of Ordnance, have been most gracious in locating material in their files and in providing free access to many of the original manuscripts. The illustrations for this chapter were made available through the complete cooperation of Dr. H. C. Thomson, chief of the Historical Branch, Office of the Chief of Ordnance. Much of the material pertaining to helmets can only be written in regard to the history of the development of a particular helmet model, and there is a great lack of medical documentation which really should be the sole purpose of this chapter. Therefore, in many ways, the relating of the development of helmets and personnel body armor would seem to be more of a history of the participation of the Quartermaster Corps and the Ordnance Department rather than the Army Medical Service. However, it is felt that there has been an intimate association and liaison between all of the interested technical services and that the inclusion of this chapter in the present volume follows a natural and logical selection of materials. Full recognition must be offered to the major participation which the Quartermaster Corps and Ordnance Department had in the development of personnel protective armor, and the inclusion of the Medical Service for consultation and advice on development of new prototypes has been gratifying.-J. C. B., W. F. E., and R. H. H.

642

Following the decision in 1917 to equip the American Expeditionary Forces with a helmet, 400,000 helmets were initially procured through the British Quartermaster's Department. Subsequently, the same type of helmet was manufactured in the United States under the direction of the Ordnance Department, and approximately 2.7 million helmets, M1917, were produced by Armistice day, 1918. The American helmet was a slightly modified version of the British Mk I helmet. The helmet was made of 13 percent pressed manganese steel alloy, 0.035 inch thick, and could be ruptured only by a blow of 1,600 pounds or more. The British helmet had twice the ballistic strength of the French helmet. The helmets of British design produced in the United States had an overall ballistic strength 10 percent greater than that of the original British helmet. The ballistics specifications of the M1917 helmet required it to resist penetration by a 230-grain caliber .45 bullet with a velocity of 600 f.p.s.

Numerous experimental models were developed to provide (1) additional protective coverage; (2) improved ballistic properties; (3) adaptability for special functions, such as machinegunner, tank operator, aviator, and so forth; (4) a more adequate suspension lining; and (5) a distinctive patriotic design. Because of the large numbers of helmets of the M1917 design which were produced in the United States, none of the experimental models developed by the U.S. Army Ordnance Department received adoption before the end of World War I. In the interval between World Wars I and II, the United States continued its research and development program on helmets in an attempt to increase the area coverage, to improve the protection ballistics limit (V50 or that velocity level at which there is 50 percent probability of a complete penetration of the test ballistic material by the projectile), and to facilitate troop acceptance by modification of the suspension system. Changes designed to improve the first two factors required careful consideration in order to be compatible with the weight and comfort limitation imposed by other testing technical services. Concurrent with the changes in weapon design were the demands for modification in the helmet specifications. With the advent of new weapons in the hands of belligerent countries, countermeasures can follow several patterns, such as increasing firepower to overcome the advantages of the new weapon, developing specific antitype weapons, or producing interim personnel protective devices.

Between 1918 and 1934, interest and progress in helmet development were maintained by the Ordnance Department and the Infantry Board. Following a series of experimental models (the model 5A was of pot-shaped design and received extensive testing before it was discontinued in 1932) and tests, it was recommended in 1934 that the M1917 helmet with a modified lining of a hair-filled pad be standardized as Helmet, M1917A1 (fig. 304). The final end item with an adjustable headpad weighed 2 pounds and 6 ounces. A lull in helmet development occurred in the period from 1934 to 1940 when the first draft call was issued. With the resurge of military life and expenditures, new overtures were made to American industrial firms and to

643the Metropolitan Museum of Art in New York in an attempt to improve the protective coverage and ballistic limit of the M1917A1 and to take advantage of recent advances in steel alloy manufacture, liner materials, and mass production methods. In addition, a two-piece helmet was considered desirable to meet the increasing variety and complexity of tactical and climatic conditions.

FIGURE 304.-Helmet, M1917A1.

The following quotation from one of the reports of the Infantry Board reveals the natural evolution of the new helmet from the original M1917 design: The ideal shaped helmet is one with a dome-shaped top following the full contour of the head and supplying uniform headroom for indentation, extending down the front to cover the forehead without impairing vision and down the sides as far as possible to be compatible with the rifle, etc., and down the back as far as possible without pushing the helmet forward when in a prone position, and with a frontal plate flanged forward as a cap-style visor and the sides and rear flanged outward to deflect rain from the collar opening.

Therefore, the M1917 model was considered suitable for protecting the top of the head and by removing its brim, by adding sidepieces and rearpieces, and by incorporating the suspension system into a separate inner liner, the World War II Army helmet came into being.3 The original test item was known as the TS3, and it received a favorable report from the Infantry Board in February 1941.

The Army M1 helmet (fig. 305) was standardized on 30 April 1941 and was approved on 9 June 1941. It was of two-piece design with an outer Hadfield steel shell and a separate inner liner containing the suspension system. The complete item weighed approximately 3 pounds, with the outer shell accounting for approximately 2.3 pounds and the inner liner, 0.7 pound.

3Studler, R. R.: The New Combat Helmet. Army Ordnance No. 132, 22: 933-934, May-June 1942.

644

Ballistic protection was afforded only by the Hadfield manganese steel outer shell with the plastic-impregnated fabric liner serving as a light-weight headpiece outside of the frontline area and facilitating the attachment of the suspension system. Various utilitarian functions were also ascribed to the outer steel shell. The ballistics properties of the outer shell had been improved so that it would resist penetration by a 230-grain caliber .45 bullet with a velocity of 800 f.p.s. The Riddell type of suspension (fig. 305C) used in football helmets was modified for the inner liner. The principle of the original Riddell suspension did not contain an adjustable headband, and this feature was developed for the helmet liner. The M1 helmet was a marked improvement over former models (fig. 306) since it furnished increased coverage (fig. 307) over the sides and back of the head and provided a more comfortable fit with the partial elimination of the "rocking" tendency of the older helmets. Following adoption of the M1 helmet, the Ordnance Department retained development and procurement of the outer steel shell and the Quartermaster Department made development and production progress of the inner liner and suspension system.

FIGURE 305.-Army M1 helmet. A. Outer steel shell. B. Inner liner. with head suspension system and adjustable headband. C. Liner with head suspension system and adjustable headband. During the course of the North African campaigns in 1943, the rigid hook fastener of the chinstrap was found to be a source of potential danger by remaining intact under the impact of a blast wave resulting from a nearby detonation and thereby jerking the head sharply and violently with the production of fractures or dislocations of the cervical vertebras. Therefore, it was necessary to redesign the helmet strap with a ball-and-clevis release so that it would remain closed during normal combat activities but would allow for a quick voluntary release or automatic release at pressures considerably below the accepted level of danger. Following extensive tests by ordnance engineers, a new release device was developed which would release at a pull of 15 pounds or more. This device (fig. 308) was standardized in 1944

645

FIGURE 306.-Helmet, TS3, later standardized as Helmet, M1 (left), and Helmet, M1917A1 (right), April 1941.

The M1 helmet was the standard item of issue to ground troops, Army and marine, during World War II and the Korean War. Before the standardization of the M1 helmet, 904,020 M1917A1 helmet bodies were manufactured from January to August 1941. During the period from August 1941 to August 1945, 22,363,015 M1 helmets were produced. Troop acceptability was fairly high, but a common complaint, was the lack of stability of the helmet. This problem had its origin, in good part, from the type of ballistic test in practice at the time the helmet was being developed. The caliber .45 pistol ball was the major test weapon, and this type of projectile with its soft lead core and thin gliding-metal jacket will deform easily against the Hadfield steel. When the helmet causes the defeat of this missile at service-weapon velocities, it will be deeply indented, and it was deemed necessary to allow a 1-inch offset

646

FIGURE 307. M1 helmet. A. Front view, illustrating offset and area coverage. B. Side view, showing increased coverage to sides and back of head.

between the helmet and the head. However, battle casualty survey studies during World Wars I and II and the Korean War have shown that the primary wounding agent among the WIA and the KIA casualties was the fragmentation-type weapon. The World War II experiences are universal except for the surveys of some of the Pacific island campaigns where small arms missiles accounted for a greater proportion of casualties. After World War II, fragment simulators in a range of 5 calibers were widely used in ballistics evaluation tests of prospective ballistic materials for helmets and body armor. The advisability or necessity of the present 1-inch helmet offset requires a thorough investigation and evaluation in the development of any new helmet. A suitable offset will always be necessary to counteract the denting of a metallic helmet or the transient deformation of a nonmetallic helmet, but the prime objective of any protective military headgear is to prevent the entrance of missiles into the cranial cavity. This entrance might be prevented over a

647

wider range of missile weights and velocities by modification of the present offset concept in helmet design. The missile defeat might result in skull fractures in a number of casualties, but the skull fracture type of injury is amenable to successful treatment by the neurosurgeon. Despite the widespread use of the M1 helmet by all the U.S. fighting forces during World War II, no definite survey was ever conducted to obtain an accurate evaluation of the value of the helmet. Numerous investigators in various surveys and separate publications in medical journals allude to the undoubted value of the Ml helmet in preventing a. considerable number of deaths and nonfatal wounds in ground troops. However, because of the marked variability of collection methods and evaluation techniques of the investigators, it is most difficult to derive an accurate correlation based on sound statistical methods.

FIGURE 308.-Ball-and-clevis release for chinstrap of M1 helmet.

Some aspects of the value of the M1 helmet are discussed by Beebe and DeBakey in their book on battle casualties. 4 More recently, Norman Hitchman 5 of the Army's Operations Research Office reviewed some of the World War II casualty statistics and reached some important and timely conclusions regarding the value of wearing a helmet in combat. The following observations resulted from this statistical analysis:

1. Of all hits upon the helmet, 54 percent were defeated.

2. For every 100 men wounded while wearing helmets, 9.6 men received wounds in the cranium. Without the helmet, it would be expected that 11.4 men would be wounded in the head.

3. The M1 helmet prevented a number of incapacitating hits equal to 10 percent of the total hits on the body.

4Beebe, Gilbert W., and DeBakey, Michael F.: Battle Casualties. Springfield: Charles C. Thomas, 1952, p. 176.

5Hitchman, N. A.: Keep Your Head . . . Keep Your Helmet. Army 8:42-44, September 1957.

648

4. The estimated savings in total battle casualties means that the helmet in World War II probably prevented wounds in more than 70,000 men. A significant proportion of these men would have been killed had the helmet not been worn.

5. To get the same amount of saving by protecting other regions, body armor weighing more than twice as much as the helmet would have to be provided.

The numerous casualty surveys conducted during the Korean War provide more accurate anatomic localization of wounds in the head region covered by the helmet as related to the total head, face, and neck region, but again it was not always possible accurately to determine whether the man was wearing a helmet at the time of wounding. One survey was conducted by Capt. George B. Coe, Cm1C, in an attempt to determine more accurately the relationship between incidence of head wounds and the wearing of the helmet. One interesting observation was related where men wearing the helmet would assume a prone position to escape missiles from a mortar or an artillery shell and upon striking the ground the helmet would be released from the head and they would sustain a head wound from a second group of shells detonating in the same area. Accurate information regarding the exact value of the helmet as a protective device is of vital importance in the training and indoctrination of troops. If it can be graphically shown that the helmet is a main line of defense against the greater proportion of projectiles commonly encountered on the battlefield, troop acceptability might be higher. Against the cast iron fragmentation projectiles which were commonly used by the North Korean and Chinese Communist Armies during the Korean War, the M1 helmet probably gave a better performance than with the steel fragments which predominated during the World War II fighting. The relatively soft and brittle character of the cast iron fragments would lend itself to low hardness and toughness and to greater ease of refragmentation and defeat upon impact against the helmet. The U.S. high explosive shell fragment has an average Rockwell "C" hardness of 29-31 and the Soviet cast iron shell fragment has a hardness of 8-14. Research programs following the Korean War have been directed toward an increase in both the ballistic protection limit and the troop acceptability under varied combat conditions. A multiplicity of factors must be reconciled and coordinated in order efficiently to effect significant changes in either of these properties. World War II investigations proved the efficacy of nonmetallic ballistic materials (nylon and doron) alone or in conjunction with metallic outer shells, but satisfactory field tests were not completed before the termination of hostilities in Korea. With the recent success of these plastics in the body armor developed for ground forces during the Korean fighting, increased emphasis has been given to all forms of research bearing upon helmet development and design.

Notwithstanding the respectable performance of the M1 helmet during World War II and the Korean War, continued improvement should be actively supported. The doldrums of peacetime can prove very lethal to worthwhile

649

and unspectacular research programs directed toward the development of items of equipment where the present standard items might appear acceptable. Any new helmet, regardless of its V50 superiority, will have to pass the ultimate test of combat troop acceptance, and this is primarily dependent upon the fit and stability of the helmet. The frontline combatant must be indoctrinated and impressed with the protective integrity and necessity of the helmet and equally with the ease and comfort with which it can be worn. Therefore, this is one field of military design where correct tailoring should be obtained commensurate with the imposed limits of the protective ballistic materials. Certain testing procedures on newer experimental helmets would appear to have been excessively delayed, and active aggressive interest in the problem has frequently dropped to a very low level.

HELMET DESIGN

Ground Troop Models

In addition to the M1 helmet, a variety of other designs were developed by the Ordnance Department during World War II. These will be discussed in the paragraphs to follow.

Helmet, steel, M1C (Parachutist's).-This helmet (fig. 309) included a modification of the M1 liner (Liner, Helmet, M1, Parachutist's) with a special chinstrap which insured that the helmet would stay on during the opening shock and descent of the parachute. This liner chinstrap was provided with a chin cup, and two snap fasteners secured the steel shell to corresponding fasteners on the inside of the liner and prevented the separation of the two components during parachute jumping. The regular helmet shell chinstrap was worn behind the head. This item was standardized in January 1945, and 392,000 helmets were produced during the period from January to April 1943. Helmet, T14 series (Signal Corps).-This was an experimental series of helmets designed to provide the combat Signal Corps photographer with maximum protection under extreme operating conditions. The standard M1 helmet restricted necessary movement and adjustments of still and motion picture cameras and prompted the dangerous habit of removing the helmet while being exposed to enemy fire. In May 1944, the Signal Corps proposed that the front segment of the M1 helmet be cut away and an adjustable, hinged visor flap be placed over the cutaway area. The Ordnance Department prepared test models which did not gain wide acceptance during field tests in the European theater. One objection was due to the fact that, when the visor was locked in its upright position, the helmet bore a superficial resemblance to the German helmet. The Metropolitan Museum of Art incorporated this problem in their work on a helmet for the Armed Forces and developed several promising models. Cessation of hostilities in 1945 prevented the completion of an end item.

650

FIGURE 309.-Helmet, Steel, M1C (Parachutist's). Helmets, T19 and T20 series (Tank).-In November 1940, Headquarters, Armored Force, Fort Knox, Ky., requested the cooperation of the Ordnance Department in modifying the then existing tank helmets to make them more compatible with the varied functions and hazards of tank crewmen. Concurrently, the Quartermaster Corps was engaged in a design of a new tank crash helmet which would offer protection from blows to the head. In 1944, subsequent correspondence requested that the tank helmet designs embody (1) a liner, incorporating a crash-type suspension, over which could be fitted a modified M1 ballistic shell and (2) the ballistic steel shell with an integral crash-type suspension. The proposed military characteristics required that the helmet would (1) protect the wearer from blows to the head during maneuvers over rough grounds, (2) be relatively light in weight with a comfortable fit, (3) permit full access to and the usage of various sighting devices, (4) permit wearing of radio headsets, (5) allow the forehead of the wearer to rest directly against the tank headrest, and (6) be capable of furnishing either ballistic or crash (bump) protection. The Ordnance Department developed six experimental series, and the Metropolitan Museum of Art evaluated the models in accordance with the Armed Forces specifications. Series T8 incorporated a ballistic helmet with a crash suspension and T9 provided a ballistic cover for the existing tank crash models (fig. 310). During this same period (1944), extensive work had resulted in a number of prototypes of flyer's helmets, and certain of these were considered as being adaptable to the needs of the combat tank crewmen. The T10 series

651FIGURE 310.-Tank crash helmets in use in November 1941.

(fig. 311A) was very similar to the helmet, T9, but provided an associated crash suspension in the steel shell. Helmet, T12 (fig. 311B) was based directly on the Helmet, M3 (Flyer's) with an internal crash suspension, and T13 (fig. 311C) was prepared without the latter feature and was designed to fit over a cut down M1 liner. The T16 (fig. 311D) series was a modified M3 flyer's helmet with a reduction in certain dimensions to bring it within the limitations of the requisite military characteristics. Between October and December 1944, helmets of the T10, T12, T13, and T16 series were tested by the Armored Force Board, Fort Knox, Ky. All the samples were found to be excessive in weight and overall dimensions and incompatible with the operation of the various sighting devices. The extensive offset and posterior extension of the helmets were developed to accommodate the radio headset and to provide adequate neck protection, respectively. In 1944 and 1945, a coordinated effort of the Ordnance Department and the Quartermaster Corps was directed toward the development of an acceptable modification of the M1 helmet shell to be used with the crash suspension-type M1 liner. Helmet, T19E1 (fig. 312) was derived from an M1 helmet shell. Changes in its contour permitted the use of various optical equipment while allowing the helmet to be used in conjunction with the new quartermaster

652

FIGURE 311.-Series of helmets. A. T10. B. T12. C. T13. D. T16. liner which offered bump protection and clearance for the headsets. An unfavorable report on this helmet was rendered in May 1945 because of the instability of the helmet-liner combination. After this work on the T19E1 helmet, helmets T20 and T20E1, produced in sample lots, incorporated a head suspension directly within the T19E1 ballistic shell. Finally, the T19E2 and T20E2 series evolved and were based upon a new contour design developed at the Armored Medical Research Laboratory. Definitive reports on these four items were not available before the cessation of hostilities in World War II. However, the consensus was to the effect that further attempts to produce a helmet for use in tanks by modifications of the standard M1 helmet should be abandoned and that the search should be directed toward a completely new and specific tank helmet design. More recent advances in the design of helmets for crewmen of combat vehicles

653

FIGURE 312. Helmet, T19E1. have made increasing use of nonmetallic ballistic materials and have attempted to provide a headgear with high user acceptability and possessing primary bump protection and secondary ballistic protection. Figure 313 illustrates the present combat vehicle crewman's helmet. The following information on this helmet was released on 25 February 1958 by the Public Information Division, Office of the Chief of Information and Education, Department of the Army: Tank crewmen will have the first helmet specifically designed for their protection when mass protection tests of a new helmet developed by the U.S. Army Quartermaster Corps are completed. Up to the present time, tank Soldiers have worn either the standard M-1 Steel Helmet with liner or football helmets, none of which met their requirements. The new helmet, officially designated Combat Vehicle Crewman's (CVC) Helmet, is constructed of multi-layers of laminated nylon fabric, and has a built-in communications system developed by the U.S. Army Signal Corps. The total assembly weighs about three pounds. Nylon employed in its construction is similar to that of the Army's armor vest. Mounted outside the helmet, the communications equipment includes a microphone on an adjustable boom, a three-way switch for listening or talking by radio or through the tank's intercommunications system, and a cable with a quick-disconnect plug for emergency evacuation from the vehicle. Inside the helmet, snug-fitting earphones reduce outside noise and help guard the ears against injury.

Helmets, T21-24 (ground troops).-Throughout the World War II period, investigative work continued in an attempt to improve the standard M1 helmet. In conjunction with the Ordnance Department and the Aero Medical Labora-

654FIGURE 313.-Combat vehicle crewman's helmet, February 1958. tory, at Wright Field, Ohio, the Metropolitan Museum of Art designed the T21, T22, and T23 series. The T21 (fig. 314) was patterned after the crown of Helmet, M5 (Flyer's), but without the earflaps and with a brim contour based on the M1 shell. Its shape had been established through anthropometric studies of the human head (fig. 315) and provided a curvature in all directions at all points on the body of the helmet. This latter feature was purported to provide a decrease in the size of the helmet with no sacrifice in area coverage while increasing the strength and protection beyond previously possible limits. The shell weighed 2 pounds and 2 ounces and was to be worn with the conventional inner plastic liner. Helmet T22 was smaller than T21, was a one-piece unit incorporating a head suspension, and was designed to be worn without a liner. Conversely, the T23 was larger in size than the T21 and permitted the use of thicker liners. In the interim between 1945 and the outbreak of the Korean War, modifications of the series just mentioned and additional new series were developed but none obtained approval or standardization. Shortly after the adoption of the M1 helmet, various investigations revealed that other materials might possess superior ballistic protective limits

655FIGURE 314.-Ground troop helmet, T21. and that these materials might obviate certain metallurgical and production difficulties inherent in the Hadfield manganese steel. In 1942, a one-piece helmet was fabricated from the resin-impregnated glass fiber laminate known as doron (p. 682). At this time, doron was under consideration primarily for use in a proposed nonmetallic helmet for civil defense workers, but subsequent tests by interested military agencies showed that existing prototypes did not stand up well when exposed to the rigors of combat life. Aluminum and nylon in combination had received extensive ballistic testing in the development of body armor for ground troops and flyers, and by 1945 samples of helmets utilizing these materials were being produced. Coupled with the high degree of protection against fragmentation-type weapons was the additional possibility of furnishing equivalent coverage to the Ml helmet with an appreciable reduction in weight. Therefore, the T24 helmet was produced consisting of an outer aluminum shell, modeled after the M1, with an inner laminated-nylon liner. Despite the cessation of World War II hostilities, the helmets were tested and deficiencies noted in the ability of the nylon insert to resist delamination and warpage. The T21E utilized the aluminum and nylon elements but was based upon the contour pattern of the T21. This pattern had evolved from scientific anthropometric studies of the human head and permitted a lower silhouette and closer fit than the M1 design. At the present time (1958), the Helmet, M1, is still the standard item of issue to Army ground troops.

656FIGURE 315.-Aero Medical Laboratory standard head models. Flyer's Models (World War II) Despite the fact that the development of protective devices for air forces combat personnel in World War II is somewhat beyond the scope of this volume, it is believed that a brief discussion of the development of some of the helmet models is very appropriate since many of the problems which were encountered were very similar to those seen in the development of certain forms for ground force personnel. The complete story of the development of protective devices for air force personnel has been written by Link and Coleman.6 This work should be consulted by all those who are interested in the medical participation in the development of helmets and body armor in the Army Air Forces in World War II. By 1943, it had become very apparent that the standard Army helmet required redesigning to make it adaptable to the needs of air forces combat personnel.7 Similar in nature but more extensive in scope, the problem

6Link, Mae M., and Coleman, Hubert A.: Medical Support of Army Air Forces in World War II. Washington: U.S. Government Printing Office, 1955, pp. 617-635.

7In 1943, Col. Loyal Davis, MC, senior consultant in neurological surgery in the Office of the Chief Surgeon, European Theater of Operations, U.S. Army, found that the regular issue steel helmet furnished excellent protection against craniocerebral injuries for the Soldier but that it did not provide the same excellent protection for crews of aircraft. He realized the necessity for a helmet designed specifically for air force combat personnel. For an account of his efforts to obtain a helmet, designed for this personnel, which would allow free and unrestricted movements, would not interfere in any way with the field of vision, would be lightweight and afford protection from heat and cold, and, most important, would provide protection, at least equal to that afforded by the regular issue steel helmet, against craniocerebral injuries, see chapter IV in "Medical Department, United States Army, Surgery in World War II. Surgical Consultants. Volume II." [In preparation.] See also Davis, L.: A Helmet for Protection Against Craniocerebral Injuries. Surg. Gynec. & Obst. 79: 89-91, July 1944.-J. C. B.

657 paralleled the work performed for the Armored Forces. Combat airmen were faced with the situation of wearing oxygen masks and goggles and earphones but still requiring some ballistic protective device for the head. Before an acceptable helmet was available, 35.7 percent of unarmored bomber combat crews sustained lethal wounds in the head region. After introduction of the "Grow helmet" or M4 helmet, this number was substantially reduced. A few of the helmet models which were developed and standardized are discussed in the paragraphs which follow. Helmet, steel, T2 (Flyer's), standardized as Helmet, M3.-This was a direct modification of the M1 steel helmet shell with an associated adjustable head suspension and cutaway on each side of the helmet body to accommodate earphones. A hinged earplate provided protection over the cutaway earphone area. Because of the immediate need for a flyer's helmet, the T2 received extended service tests and was eventually standardized in December 1943 as Helmet, M3 (fig. 316). This helmet weighed 3 pounds and 3 ounces. Between December 1943 and April 1945, 213,543 helmets of this type were produced. During its development, it was recognized that this type of helmet was unsuitable for a number of confined combat stations where a closely fitting skullcap type of helmet was necessary.

FIGURE 316.-Flyer's Helmet, M3. Helmet, steel, T3 (Flyer's), standardized as Helmet, M4.-During the early part of 1943, the Eighth Air Force had combat tested a skullcap type of helmet, and the Ordnance Department proceeded to develop prototypes based

658

upon this design and field experience. By September 1943, this model was being tested in conjunction with the T2 model. It consisted of overlapping Hadfield steel plates which were enclosed in cloth pockets and mounted in the skullcap cover of fabric and leather. Openings were available on the lateral aspect of the helmet to permit the wearing of headphones. Notwithstanding the decreased protective coverage of this helmet, it could be worn in the restricted space of aircraft turrets where a larger one would not be acceptable. This helmet was standardized as Helmet, M4, in December 1943 (fig. 317A). It weighed 2 pounds and 1 ounce. In February 1944, it was recommended that the length of the M4 be increased to provide an adequate fit over all types of summer and winter leather flying helmets. Helmet, T3E3 (Flyer's), standardized as Helmet, M4A1.-Shortly after the M4 became standard issue, it was apparent that armored earplates were required, and a number of experimental models were developed and tested. Finally, by April 1943, the T3E3 was adopted to replace the M4 and was standardized as the M4A1 (fig. 317B). It differed from the M4 by having a slight increase in length and by being equipped with attached metal earplates over the temporal regions. This helmet weighed 2 pounds and 12 ounces. A method was also devised to equip the existing M4 helmets with a fitted hood containing metal earplates. In addition, the M4A1 was later modified (M4A2) to improve the attachment of the earplates and to increase its compatibility with other flying gear. After the adoption of the newer model, a considerable number of experimental helmets were developed and tested in a continuing effort to produce a universal air force helmet with extended area coverage, increased protective ballistics limits, wearer acceptability, and compatibility with associated flying goggles and headphones. Because of fabrication difficulties with the overlapping steel plates in M4 helmet series, emphasis was centered upon a one-piece closely fitting helmet bowl with attached earplates. In addition to the Hadfield manganese steel, a number of other metallic materials were considered, and at one time aluminum seemed to provide the promising combination of comparable ballistic protection at a somewhat lower weight. However, during World War II, Hadfield steel continued to be the principal ballistic material for helmets. Helmet, steel, T8 (Flyer's), standardized as Helmet, M5.-The helmet, T6E4, had a single steel bowl with no associated suspension system, fitted close to the head, and had large hinged earflaps. It was a most promising model, and future modifications originated from the T6 series. The T8 models were based upon the specifications of the T6E4 but incorporated numerous design changes which increased its acceptability over previous models. The helmet consisted of a one-piece steel bowl with a head suspension system and hinged earplates or cheekplates which extended down on to the sides of the face in line with the leather flyer's helmet. The usual webbing suspension system was augmented by a nape strap that held the front of the helmet against the forehead so that there would be no interference with vision. The cheekplates permitted the wearing of earphones and goggles. One additional mod-

659FIGURE 317.-Flyer's helmets. A. M4. B. M4A1. C. M5. ification provided a slight roll to the back of the helmet to reduce the possibility of injury to the neck region during crashlandings. In January 1945, the T8 was standardized as Helmet, M5 (fig. 317C), and was designated for all combat aircraft positions except the upper turret gunner of the A-20 and the ringsight gunner of the B-29. The M4A2 was still used in the two positions just mentioned. The M5 helmet weighed 2 pounds and 12 ounces. Between February and August 1945, 93,495 helmets of this type were produced. During the period from October 1943 to July 1944, numerous designs for face armor were studied concurrently with the development of flyers' helmets. Most of the models were intended to be worn in conjunction with the helmet and were to provide protection over the lower part of the face, the neck, and the oxygen mask. Both metallic (fig. 318) and nonmetallic materials were tested. The project was suspended in 1944 because of the lack of specific requirement for this type of armor.

660FIGURE 318.-Face armor (T6 type) designed to be worn in conjunction with the flyer's helmet. BODY ARMOR "Body armor is not new."8 Some form of personnel protective device has probably been used in every war which has been recorded in the pages of history. During the Civil War,9 a number of types of protective shields and breastplates were developed by interested parties, and some of these were considered for possible official military usage. However, no standard official form of armor was available, and all forms were purchased by individual Soldiers. Two types have been described as being most popular among Union Soldiers. These consisted of the "Soldiers' Bullet Proof Vest" manufactured by the G. & D. Cook & Company of New Haven, Conn., and the second most popular

8I have used this simple statement as the introductory remark in numerous lectures given on the subject of the history of body armor, and it certainly expresses the course of body armor development in modern times.-W. F. E.

9See footnote 1 (6), p. 641.

661

type of breastplate was manufactured by the Atwater Armor Company, also of New Haven. Both types consisted of metallic ballistic material made up of a number of steel plates. The product from the Cook & Company consisted of two pieces of steel inserted into pockets in a regular black military vest. The infantry vest weighed 31/2 pounds, and another model for cavalry and artillery weighed 6 pounds. The purchase price of a vest for an officer was $7 and for that of a private was $5. The Atwater armor consisted of four large plates of steel held in position on the body by broad metal hooks over the shoulders and a belt around the waist. In addition, smaller pieces could be attached to the bottom of this cuirass. This vest was heavier than the Cook models and cost approximately twice as much. The supply of these finished commercial products was augmented by specimens of armor apparently of individual manufacture by some local blacksmith. During the course of his investigations, Dr. Bashford Dean of the Metropolitan Museum of Art was able to test the Atwater armorplate and found that it would defeat a jacketed bullet fired from a caliber .45 pistol at a distance of 10 feet. In his short but excellent discussion of body armor in the Civil War, Harold L. Peterson felt that the chief factors in the discontinuance of body armor at that time were the inconvenience due to the extra weight and bulk and the marked ridicule of those individuals who were wearing the armor by their comrades who did not avail themselves of the protection. Dr. Dean in his "Helmets and Body Armor in Modern Warfare" presents a complete account of the history of body armor during World War I. Most of the participating countries developed various forms of protective devices for the torso and the extremities, but the excessive weight or lack of adequate protection restricted their general use in combat. Some form of body armor was seen on all fronts from 1915 through 1918, but only on experimental basis, and body armor was never in general usage. The most successful use of armor was by sentinels, members of patrols, and stationary machinegun crews. Despite the relative low troop acceptability because of excessive weight, it was generally believed that these forms of personnel armor had great potential value. General Adrian who was instrumental in developing the French helmet was also interested in a number of other devices, including an abdominal shield, a breastplate, and leg armor. Some of the medical officers investigating the casualties of British forces through the year 1916 indicated that more than three-quarters of the wounded men could have been saved if some form of armor had been worn. This assumption was based upon a study of the type of wounds (penetrating rather than perforating) and the preponderance of causative missiles being derived from fragmentation-type weapons (either shrapnel or shell fragment). Similar statistics were derived from studies of French casualties where it was believed that 60 to 80 percent of all wounds were produced by missiles of low to medium velocity. Maj. Charles H. Peck, MC, Assistant Director, Surgical Service, American Expeditionary Forces stated: "Wounds caused by missiles of medium and low