BREAKING NEWS!

Caveat: tracks are just as fast as wheels EVEN ON STEEL TRACKS. Most are governed and lack the necessary power to go above 45 mph. Give them the power tracks can go 60+ mph. Wheeled armored trucks have a weight DISADVANTAGE.

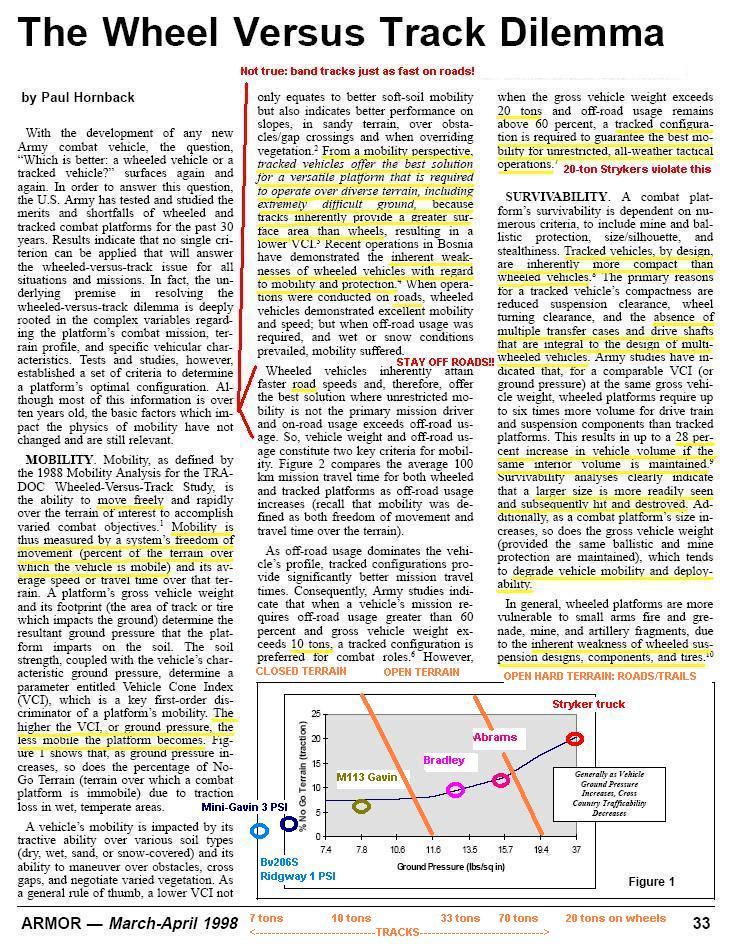

Paul Hornback's Wheels vs. Tracks Article in the March-April 1998 issue of U.S. Army Armor magazine (before it became politicized) Warned Us Against the Wheeled SASO "Nation-Building" Racket EuroFad

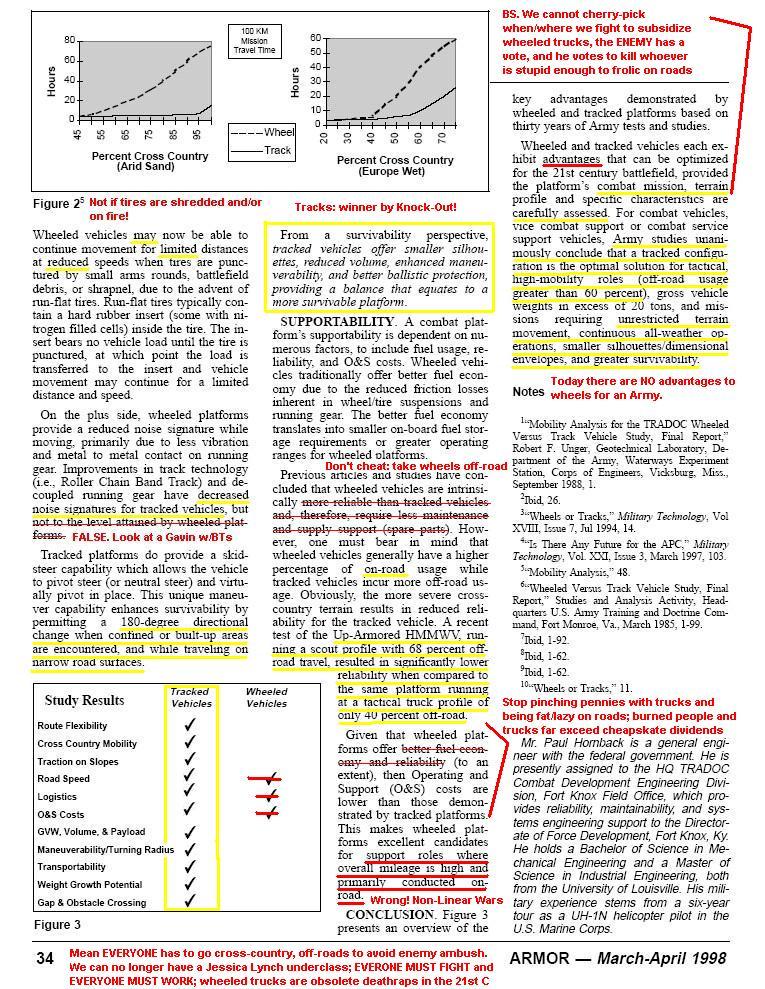

Steel Tracked M113 Gavin went 75+ mph in 1979! There's NO justification for wheeled trucks on the non-linear battlefield!

According to Hunnicutt Bradley: A History of American Fighting and Support Vehicles on page 109, the "Hot Rod" averaged 75.76 mph over a 500 foot gravel test track at Fort Knox in 1979. Power was 2 x 440 cubic inch Chrysler gas engines driving two modified 727 transmissions.

Imagine what M113 Gavins would do today on band tracks with hybrid-electric drive!

www.combatreform.org/bandtracks.htm

www.combatreform.org/hybridelectricdrive.htm

...thanks be to retired LTC Dave Tooker for finding these pictures!!

Single-piece band tracks are not too hard to repair as this web page proves in detail.

www.defensenews.comU.S. Army Chooses Molded Rubber Track for FCS

By GREG GRANTThe U.S. Army has decided to equip its Future Combat Systems' (FCS) manned ground vehicles with a molded rubber band track.

The band track resembles a giant steel-belted radial tire and weighs significantly less than metal tracks, a key design consideration in the FCS ground vehicles, which are intended to be lightweight and air transportable.

There had been some question as to whether the FCS vehicles would be tracked or wheeled. Proponents of both designs within the Army argued vehemently.

For vehicles weighing more than 30 tons, particularly when driven over loose terrain, tracks are a better choice because they distribute the tonnage over a greater surface area, reducing the all-important vehicle ground pressure. A heavy wheeled vehicle will just dig into soft or sandy ground and has poor mobility over wet ground or snow.

But at weights below 10 tons and on vehicles driven primarily on roads, wheels make more sense. They're quicker and considerably cheaper than tracks.

"The problem with FCS is that its weight is in the 25-ton range, which is a gray area where it could go either way," said Michael Blain, team leader, Track and Suspension Team, of the U.S. Army's Tank-automotive and Armaments Command's (TACOM's) Tank Automotive Research Development and Engineering Center.

Blain said heavy tracked vehicles are more compact than wheeled ones, which require multiple axles, transfer cases, drive shafts and space to turn - all of which adds up to a bulkier, taller vehicle.

Tracked vehicles turn by "skid steering," and so do not require a steering arm or under-vehicle suspension. This lowers the vehicles' profile, increasing survivability and making it easier to fit a tracked vehicle inside a cargo aircraft.

Wheel proponents argue that multiple-wheeled vehicles can keep running if a wheel is knocked out by a mine, but the tires and suspension system are vulnerable to small arms fire and artillery fragments. The greatest argument in favor of wheels had always been the weight advantage.

But Blain's team at the development center has come up with a new technology, the band track, which should save around 1 ton per vehicle. He said it creates a nearly tailor-made solution for the weight-sensitive FCS program.

The band track combines the aggressive cross-country, wet or soft ground and snow performance of tracks with the road-friendly ride of wheels. Tests show the service life of the hard rubber track should be nearly double that of traditional metal tracks. In Iraq, the Army has been replacing the metal tracks on its heavily used Bradley fighting vehicles every two weeks.

The band track offers much less rolling resistance than metal track links, which means less inertia to overcome to get the vehicle rolling; this saves fuel. And the rubber track and rubber road wheels give a much smoother ride than the severe vibration characteristic of steel tracks.

Another benefit: Rubber band tracks are much quieter than metal ones, particularly on a hard surface, said Herb Muktarian, of BAE SYSTEMS, who is involved in FCS ground vehicle development. "When combined with the FCS vehicle's hybrid electric system, the band track helps provide a touch of stealth" to even a 25-ton vehicle, he said.

There are a few drawbacks. The band track's light weight makes it more vulnerable to mine blast than steel links. Conversely, the band track has proved more resistant to small arms fire than metal tracks.

Repairs are another drawback. TACOM's band tracks are made in one continuous piece, like a giant rubber band. To replace the track, Soldiers need to haul along another continuous band, which is not entirely feasible. Individual metal track links can be replaced much like the links in a bike chain.

"Commanders of the FCS program said, 'This stuff is great, but if you could chop it into little segments, then we could maintain it in the field a lot easier,'" Blain said.

Blain's group is now working on developing a segmented track with a joint similar to that on existing metal tank and Bradley tracks.

E-mail: ggrant@defensenews.com.

Bandtracks are key track technologies some Army officials are either unaware of or want you not to be aware of----that solves all of the petty complaints with tracks ("O, they are too noisy, my men are too pooped to dismount", "they require more maintenance" etc. etc.), giving a tracked vehicle ALL of the best attributes of wheels and tracks. I suspect because a high-tech tracked vehicle wouldn't LOOK sexy and "RMA" new enough even though it out-performs the wheeled armored cars, so it will not be utilized? Emotions for a change in style to support Tofflerian/RMA hubris are driving decision makers not factual, performance reality.

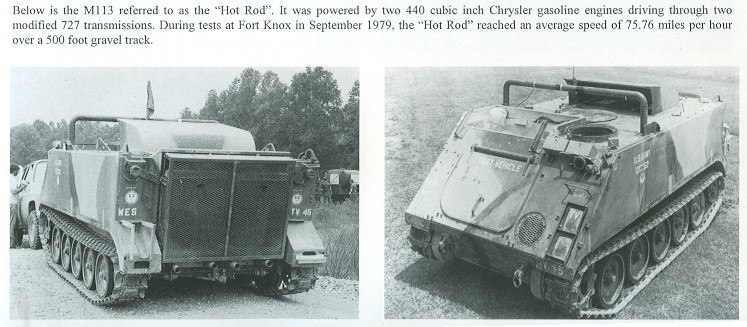

First, new steel T150 tracks with rubber pads have double pins and are available NOW for M113 Gavins for direct fire close combat actions. As fast as the engine power will drive you, you can go. With Hybrid Electric Drive, a M113A4 Gavin will have over 500 hp for just a 10.5 ton vehicle! That's 50 hp/ton! That's twice the power-to-weight ratio of the M1 Abrams heavy tank! According to Hunnicutt's book; "Bradley: a History of American Fighting and Support Vehicles" on page 109, a M113 Gavin with two gas engines (more power) reached 75.76 mph on steel tracks with rubber pads at Fort Knox in 1979. Its all about the power you make available.

Video Proof that even steel tracks with rubber pads can go 60+ mph on paved roads: private owner has his Scorpion light tank street legal in England/France

"With a width of 17 in. (432mm), the lightweight steel tracks have rubber pads on both the road and road wheel sides to minimize noise"

--Chris Foss & Simon Dunston, Peter Sarson: "Scorpion: reconnaissance vehicle 1972-1994", page 13, Osprey New Vanguard Books, London, England, 1995

This should end the "only Stryker/Humvee trucks can do 60 mph on roads to do certain tasks" non-sense forever. Take the governors off our tracks and they can go as fast as you want them. There is NO reason to have or use vulnerable rubber-tired trucks on the non-linear battlefields of today...they need to go the way of the horse cavalry.

www.combatreform.org/steeltrackscango60mphonpavedroads.wmv

Full Clip with Short History of Tanks

Recent Productions

http://72.14.207.104/search?q=cache:FFlc_wMMrHAJ:www.pioneertv.com/recent.asp+tycoon+toys+national+geographic&hl=en&ie=UTF-8

Tycoon Toys

(2 x 60' for National Geographic Channel/Freemantle International Distribution) are what the super-rich choose to spend their hard-won zillions on. We meet the few individuals who have a particular penchant for owning, driving and firing huge pieces of ex-military hardware, from field guns to tanks to fighter jets. Tycoon Toys goes on a journey to watch them at play. 2004 - Distributed by: Freemantle International Distribution

The Steel Tracks with rubber pads to go 60+ mph!

Improved T150 track Extensions?

Can you go through this kind of mud in a Humvee/Stryker truck?

Hardly.

What's fascinating is we can even improve the Gavin's cross-country performance by lowering its already low ground pressure even lower!

http://www.geocities.com/armorhistory/T150trackextensions.htm

Falklands War decision: what would U.S. light infantry do if in same situaion (hint: Red China in the far east)?

Brigadier Julian Thompson in his book, "No Picnic" on page 11 writes:

"I was decided at an early stage in planning to take the minimum number of wheeled vehicles. The going anywhere in the Falklands away from the settlements was so bad that even a lightly loaded Landrover would be lucky to cover four miles an hour. Vehicles loaded with ammunition and stores would be lucky to move at all. The Brigade did have seventy-six of its BV202 oversnow vehicles in England, the remainder being stockpiled in Norway. Although designed to operate over snow there was a good chance that these vehicles with a ground pressure of only 1 1/2 lbs per square inch, about that of a man on skis, would be able to motor across the peat bog. Events were to prove they could."

How many tracked vehicles do U.S. Army light infantry units have?

ZERO.

Unfortunately, the Army's light units with Delta Anti-Tank (AT) Companies use unarmored, High-Mobility, Multi-purpose Wheeled Vehicles (HMMWV or "Humvees"); mere 4x4 trucks without the cross-country mobility, armor protection or space in the back to carry A, B, C Company infantry Soldiers as required to conduct real world missions such as rapidly fanning out from Drop Zones (DZs) or Landing Zones (LZs) into enemy territory to engage fleeting asymmetrical enemies as depicted in the scenario above. The Humvee, as a wheeled sport utility not combat vehicle, simply cannot go cross-country at will through vegetation, soft soils, or up and down slopes. It is often road or trail bound, and thus easily ambushed and destroyed at Combat Training Centers (CTCs) like the Joint Readiness Training Center (JRTC) and sadly in combat in Afghanistan and Iraq. Wheeled vehicle are 28% less capable of armor protection than more weight/space efficient tracks. When you slap all kinds of armor on it, Humvee and 8x8 Stryker truck mobility degrades further and mechanically it starts breaking down. The Humvee immobility is vividly described by Brigadier General Dan Bolger in The Battle for Hunger Hill and more ominously by real casualty reports in recent combat actions in Iraq, not to mention the 1993 Somalia raid described in the book and film; "Blackhawk Down!" Both the HMMWV and Strykers are trucks, not combat vehicles, with air-filled rubber tires easily punctured and set on fire in a firefight resulting in a mobility kill, and potentially a "total kill" if the men inside do not get out of the vehicle. Delta Companies and AT platoons, are the main organic anti-tank and mobile security force for foot-mobile light infantry, must not be easily attrited or else the entire main body will be placed in a position of having to fight for its life. The Army's light units doing 3D maneuver warfare like the Airborne must land and take the fight aggressively to the enemy without having a "glass jaw;" they must be able to fire and maneuver at will anywhere on the terrain and shrug off enemy fires encountered to attain important objectives - not be damaged and immobilized. THE ORIGINAL PURPOSE FOR THE M113 GAVIN WAS AIRBORNE WARFARE: the program title was "Airborne Armored Multi-Purpose Vehicle Family".

Band Tracks: Ready to End Use of poorly Armored Wheeled Trucks in Non-Linear Combat Zones

www.youtube.com/watch?v=RbWbkOkTydk

We don't need less protected trucks when we can go just as fast in better protected tracks.

Also remember the current M113A3 Gavin with steel tracks has a governor on restricting its speed.

Band Tracks: Already Proven In Combat with 6 decades of Half-Tracks

Its been staring at us in the face for years.

"Band Tracks" have already been in U.S. Army/marine use for DECADES as the maintenance free tracks on HALF-TRACKs. The M2/M3 family of half-tracks as an inexpensive thinly armored vehicle with modest cross-country capabilities but certainly far better than today's bloated Strykerrrr trucks--were mass produced in the thousands during WW2, and after they helped us win that war, saved us in Korea when we were not ready. 13, 058 M2s and 12, 499 M3s were built according to Jin Mesko in his 1996 book, "M3 Half-Track in Action". Only the mighty M113 Gavin's 30,000+ numbers exceed the half-track's production totals. It is mystery however why with Army success with band tracks on M2s/M3s and on the M114 recon vehicle (the problem was with its hull overhang) why its taken us so long to get around to offering band tracks for M113 Gavins?

Bv206S Ridgway

For zero maintenance, stealth and 60+ mph road speeds with smooth riding comfort, "Band-tracks" are already in use by Army BV-206 SUSVs and German Airborne Wiesel tracked vehicles. And now the Canadian and Norwegian Armies on their advanced M113 Gavins in Afghanistan combat operations! A band tracked M113 Gavin would be perfect for the Army's light infantry Delta Weapons companies to replace their fragile Humvee trucks to have superior armored mobility, firepower and smooth riding stealth that enables Alpha, Bravo and Charlie companies to have a ride as needed without bogging them down in motor vehicle care.

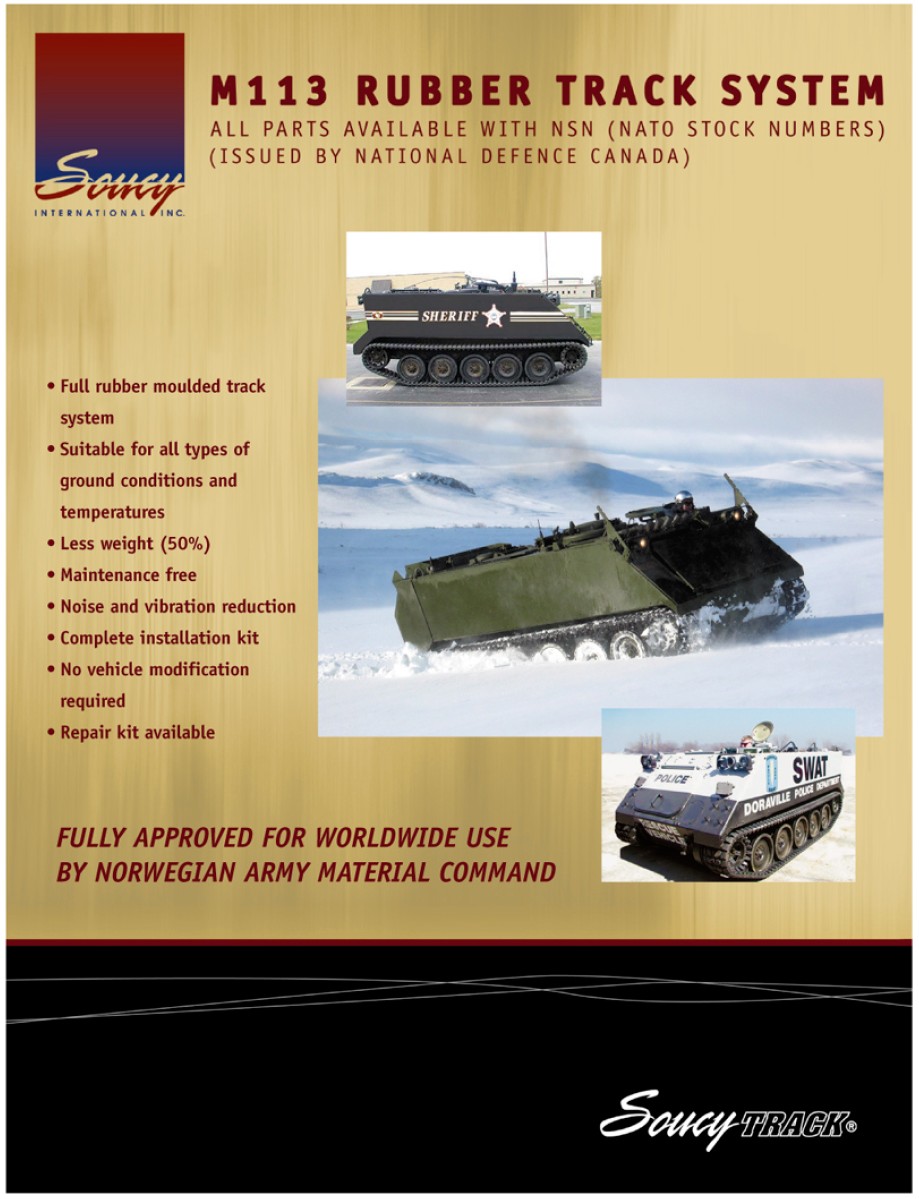

NEWS FLASH! Canadians and Norwegians using engineer M113 Gavins w/band tracks for Afghanistan

The Canadian and Norwegian Armies actually have put band tracks on M113 Gavins with mineplowing/rolling devices for Afghanistan, when Canada picked up command of the NATO force there this year. We don't have a picture of it, but the guys at Soucy outside Montreal are making the track.

Mine plow M113 Gavin info:

www.geocities.com/armysappersforward

Does advanced technology favor wheels or tracks?

What can a wheeled vehicle do that a vehicle with band-tracks can't do BETTER?

The answer is nothing.

Consider a band-track a giant steel-reinforced tire stretched around road wheels but without the drawbacks of needing air to hold its shape or only a small area in contact with the ground. Its the best of both worlds. General Shinseki said we would "go where the answers are", the answers are found in tracks not wheels, though the Army's hypocrisy is now apparent after choosing the fatally flawed 19-21 ton LAV-III "Stryker" death car for IBCTs. The Army's wheeled computer madness persists even after Shinseki's retirement.

Description of Band-Track Technology

Band track is an emerging alternative for the segmented metal track that is typically used on tracked combat vehicles. Band-track provides a lightweight, continuous alternative that smoothly travels around suspension elements with minimal vibration input to the hub and the ground. Band track is constructed of high-performance rubber molded around polymer fibers and/or steel cables that give the track the required tensile strength. The rubber is molded in such a way that the ground contact pads, roadwheel running surface, internally reinforced center guides and sprocket drive lugs are integral. This track offers significant improvements to vehicle performance as well as Soldier comfort and effectiveness. The photograph at the link above shows an M113 Gavin fitted with band track. The German Wiesel 1/2 and Swedish BV-206 family (SUSV in U.S. Army use) have used band-tracks for years to include combat in Somalia.

Benefits of Band-Track Technology

Following are recorded benefits relative to T130 steel track based on M113 Gavin testing by TACOM/TARDEC at Yuma Proving Ground, and by United Defense at Pelham Range, Fort McClellan in Alabama.

·* Weight - Reduced by approximately 50% of standard T130 steel track

* Cost - 10% less than T130 steel track

* Durability -4000+ miles

* Noise - Reduced by 6 dB (A), interior and exterior (reduction to level comparable to heavy truck)

* Vibration Reduced by 30% (70% in actual field use)

* Maintenance - Minimal to negligible. There is no periodic replacement of pads, no tightening of pin fasteners, no blocks to replace.

* Road damage - Negligible - No metallic components to contact road.

* Roadwheel life - Improved - Continuous running surface/non-metallic guides

* Low mass and inertia - Improved acceleration, improved braking

* IR/EM signature - Reduced

* Rolling Resistance - 17% - 35% less than T130 on hard surface

* Aggressiveness - Comparable to steel track; better in mud, snow, and ice

* Bullet-resistant

Disadvantages somewhat of Band Track Technology

There are currently some disadvantages relative to existing steel track, which United Defense/SII are working to mitigate.

* Field installation is somewhat more difficult (currently, two Soldiers can change track in about an hour and one half). See details below.

* Somewhat more susceptible to mine damage (mine resistance has not been yet incorporated into the design -this will occur over the next year).

* There is a new repair limp-home kit that will require different procedures to employ.

Technology Development Status

United Defense's partner, Soucy International Incorporated (SII) located in Drummondville, Quebec, has a long tradition of manufacturing band tracks for snowmobiles, recreational vehicles, agricultural machinery, snow blowers and other types of equipment. In the late 80's, work on the development of band tracks for military vehicles led Soucy to produce tracks for the SISU (Finland) articulated vehicle that led to a 3X-4X increase in life over the track it replaced. In the early 60's, work was performed for the MOD UK and Alvis to develop a track for the Spartan vehicle. In the same period, work was also initiated with TACOM (U.S. Army Tank Automotive Command) and I.S.T.C. (Industry, Science, Technology Canada) to develop 15-inch band track for the M113 Gavin Family of Vehicles. These development programs have shown that band track has the potential to replace steel tracks in light and medium weight military vehicles.

Soucy is also currently under contract with TACOM to develop a band track for demonstration on a medium-weight 50,000-pound Bradley Fighting Vehicle. This track is nominally 18 inches wide and may find application in the Future Scout Combat System (FSCS) and Future Combat System (FCS) if s wisely tracked not the latter is wisely tracked not wheeled. The first sets are currently undergoing development testing at Yuma Proving Ground. Band tracks are already proven on 17-ton M8 Buford/Thunderbolt AGS light tanks with both 105mm and 120mm guns.

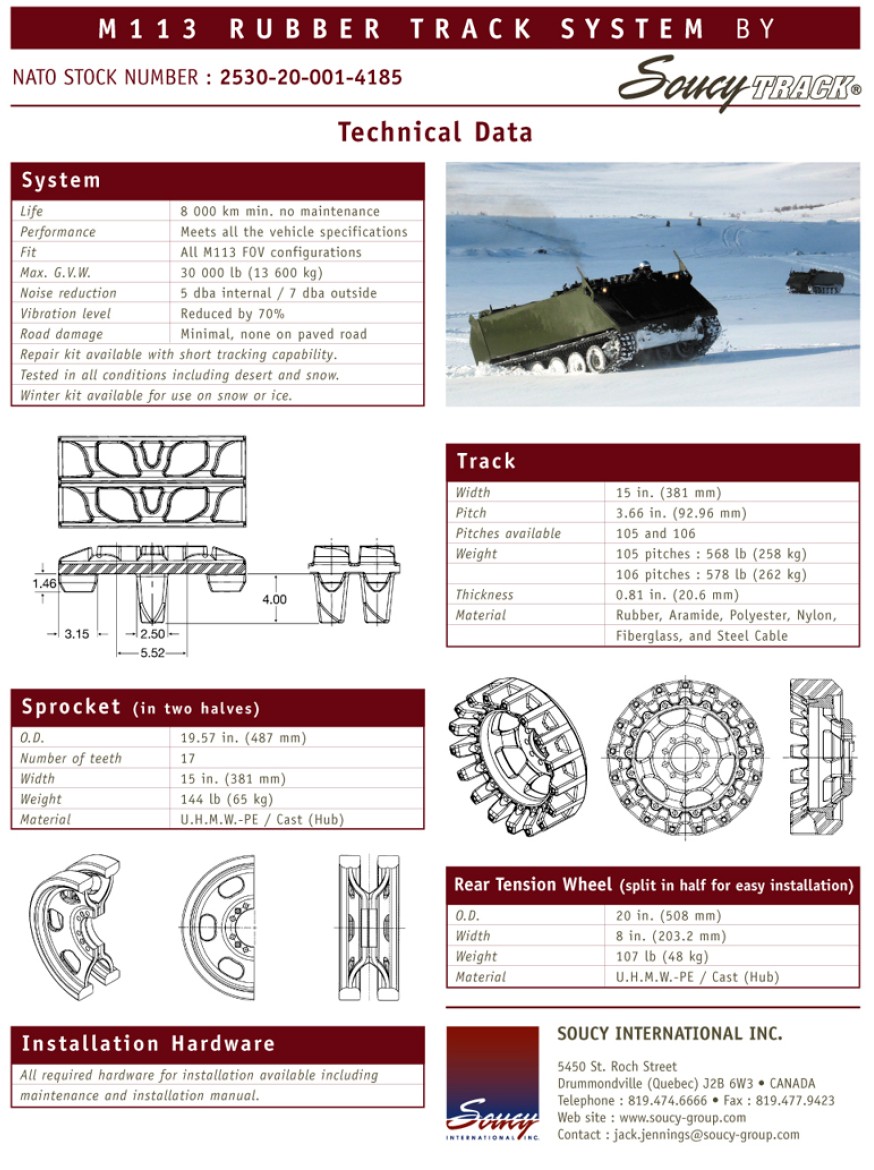

In 1999, Soucy and United Defense entered a partnership to bring band track into maturity for combat vehicles. The overwhelming majority of the testing and development effort has been aimed at the M113 Gavin family of vehicles, which is the nearest-term opportunity for actual fielding. Soucy's bandtracks are ready for implementation on M113 Gavins and in use in Norwegian Army M113s in Afghanistan where they have done 500 kilometer missions at 70% less vibration over steel tracks and now has a NATO Stock Number (NSN): NSN 2530-20-001-4185

Soucytrack(r) System Description

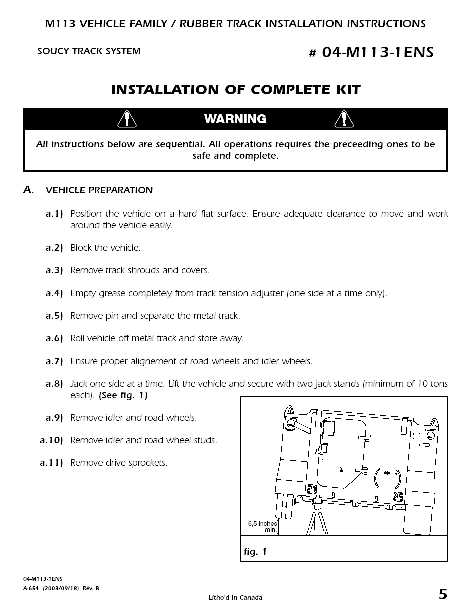

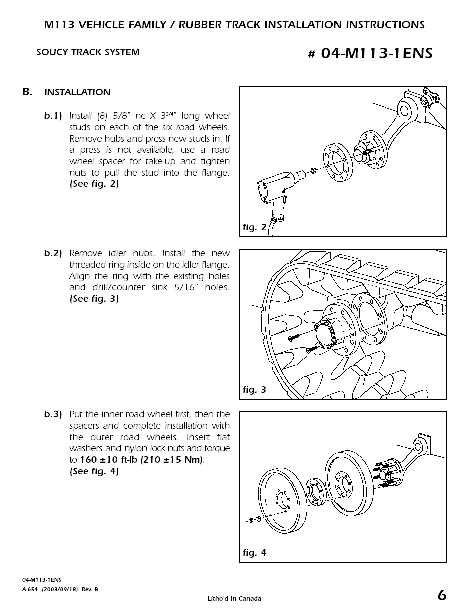

The basic system consists of:

*2 Rubber Tracks

*4 Half-sprockets

* 4 Split idlers

*Hardware (bolts, spacers & back plate)

*No vehicle modifications required

Installation & Maintenance

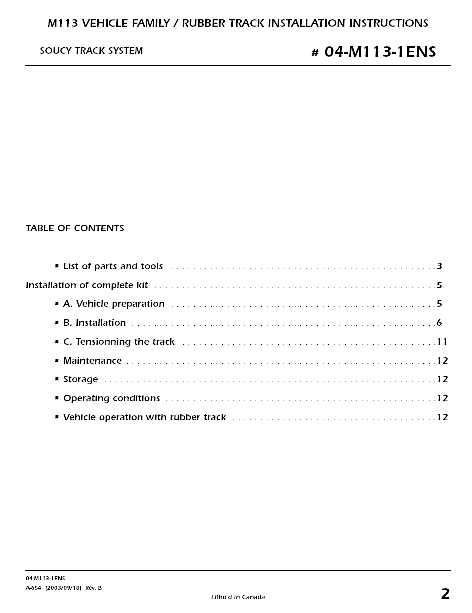

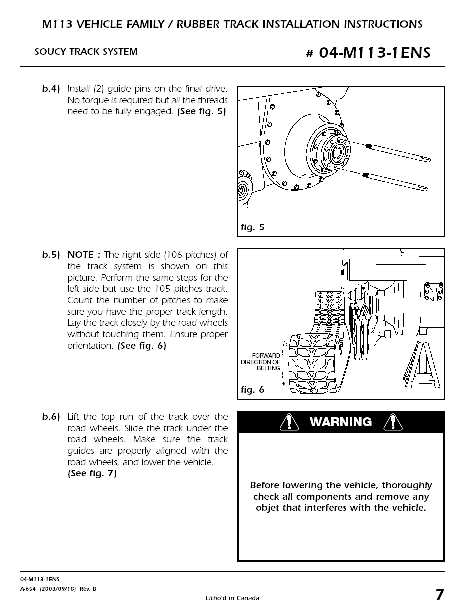

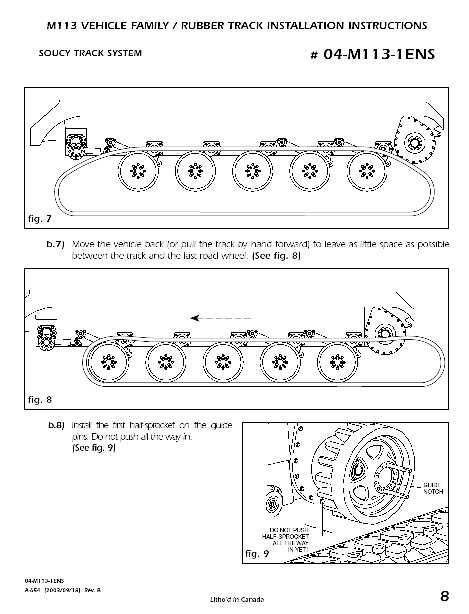

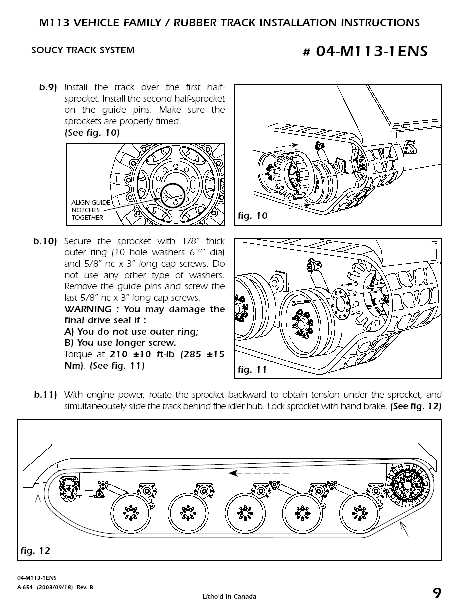

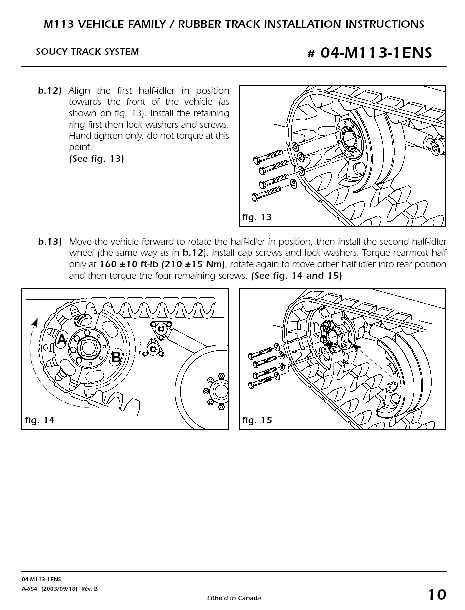

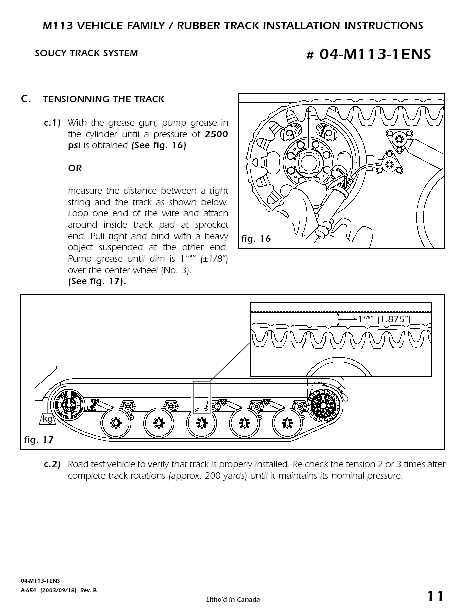

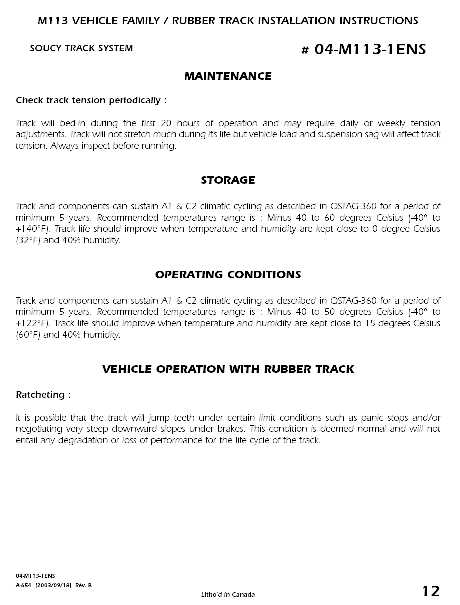

How to Install Band Tracks on a M113 Gavin

PDF File www.combatreform.org/SoucyBandTrackInstallationA-654RB.pdf

Click on thumbnail to see full size picture of the installation manual:

* Canadian Soldiers have commented that "the Soucytrack(r) System is virtually

maintenance free".

* NO track maintenance required = makes tracks easier to maintain that rubber-tired trucks

*DND Canada report states that "man-hours required for installation is reduced 50% compared to steel track".

*There are no rubber pads or bushings to replace.

*No end connectors to torque.

*Dramatic increase to road wheel life.

* Repair kit is available which enables the vehicle to be driven to a safe area or repair vehicle for track replacement. The repair kit has variable length capabilities so short tracking is not necessary if roadwheels are intact. Secondly, track now has steel cord so tracks do not break as was a case during development Soucy used Kevlar cords.

Norwegian Army uses air bags to lift one side of the vehicle (standard procedure for their steel tracked vehicles, also). They have installed tracks without even lifting the vehicle, though Soucy does not recommend this, as you might damage the tracks.

Vehicle performance

* Acceleration: improved by 15% to 25%

* Braking: Improved by 20%

* Mobility: Equivalent or increased since band tracks have actual treads for traction

All test, field and combat reports in hand conclude that the vehicle performance is improved or unaffected with the rubber track system as compared to standard steel tracks.

* Reduced vibration by 70% = greater Soldier comfort and energy to fight

* Smoother ride enables Soldiers to be rested for combat

What if the band tracks breaks? Unit-Level Recovery Options

1. If majority of band track is usable, SPLICE it together using the repair kit over the still functtional road wheels ("Short track" if a bomb blast has taken out roadwheels etc.).

2. If all that has happened is your band track has been destroyed and there is not enough band track to splice, use a new single-piece, band track if you have one in your convoy/formation.

If you do not have an extra band track in your unit convoy/formation, and there is not enough band track or tracks to splice together, REMOVE THE OTHER GOOD BAND TRACK (if applicable) and TOW THE GAVIN BY ITS REMAINING ROADWHEELS. Below are pictures from Vietnam showing that this can be done.

"91% of the Soldiers exposed to the system preferred it over standard steel tracks" (Canadian Army Test Establishment)"

The Soucytrack(r) System for M113 has been fully tested and approved in all types of climatic and ground conditions.

Soucy recommends that the U.S. Army make a multi-vehicle assessment using different locations to demonstrate the benefits they can receive by using Soucytrack(r) System.

www.soucy-group.com/English/interdivision/app_mili.htm

Soucy Holding inc.

5450, rue Saint Roch

Drummondville (Québec) Canada J2B 6W3

Telephone : (819) 474-6666

Fax : (819) 477-9423

URL : www.soucy-group.com

General Information : info@soucy-group.com

Curriculum Vitae : rh@soucy-group.com

An Army Combat Veteran writes:

"Mike,et Al.

I was working for the Armor School in 1982 and drove M1s (not even M1A1s) without any governor at 55-60 MPH. It was faster then than the wheeled hauling the fuel.

It's never been 'facts' it's always been about attitude: Tracks = BAD, wheels = GOOD."

A combat developer writes:

"Several years ago --maybe 5--at Ft. Dix I clocked an Abrams running 20 yards to my right at 60 MPH. I was in a pickup on the post road--he was on the track road parallel to it. As I recall; he showed me he was not wide open."

An experienced Australian Army Soldier writes:

"Australia used T130E3 until recently. Used Diehl dual-pin track for 6 years in extended trial with two units. I believe T150 has been tasked for the upgrade M113AS3/AS4. I am aware of T150 with rubber pads. I can only speak from Aussie experience. Australia used T130E3 until recently, exclusively with rubber track pads. Pain to change out, but made civil road authorities a lot more friendly to our cause. T130 is actually a lot more quiet than other steel tracks, like the German and Korean dual-pin types (know from trials, an M113 with Diehl track passing by 6 feet away at 50km/h - 30 mph is loud enough to make you feel sick). Using vulcanized idlers also kills a lot of high speed noise, as it dulls the slap of track on the idler. Most heavy tanks use vulcanized idlers.

Speed isn't the exclusive domain of rubber track either. Road runs in M113A1s (no fancy hydraulic steering, just sticks) fitted with Diehl dual pin track regularly saw them hitting 52 mph on flat level asphalt. We'd sometimes get quicker on cold days. With stronger tracks, its only the governor holding them back.

As far as the LAV family making white 'ninja' approaches on anything, its still the same base 53 series engine, not particularly quiet, and with the LAV/Stryker blower AND turbo, they make a fair whine. They're also fitted with a Jacob's Brake, coupled to the accelerator. If you come off the accelerator in any hurry, you sound like a Mack line haul truck coming into town.

LAVs remind me of fighter jets. They go fast. The politicians love them, they're at all the open days, and they spend twice as long in the hangar and workshops. Do the same job by making compromise after compromise. Fucking fair weather A vehicle. The Bushmaster turret is the only good thing going on a LAV."

For more of Chris Ashby's amazing artwork and cartoons: www.elusive-concept.com