WW2 Re-Think: Was there a Way to Get American Infantry Squads a Sustained-Fire Light Machine Gun like the Germans Had? How About Detachable Magazine and Stripper Clip-Fed Rifles?

By Mike Sparks

Browning Automatic Rifle: Not a Light Machine Gun?

They say "hindsight is 20-20"...as if we have somehow have no right to learn from the actions of people from our past...or be critical of their mistakes?

Wrong.

Let's use that clear examination of the facts to learn something to help us for today and the future. Then U.S. Army Major, E. Paul Melody in his excellent 1990 School of Advanced Military Studies (SAMS) paper explains why U.S. infantry in WW2 that had 20-round magazine-fed, fixed barrel, often bipod-less, Browning Automatic Rifles (BARs) which while shooting the powerful 7.62x82mm (30.06) cartridge was not as good as German infantry which had the belt-fed, large caliber 7.92mm MG42 light machine guns (LMGs) with pistol grips--whose barrels could be changed for sustained fires to keep their opponents pinned down. Thousands of our men died or were maimed because of this.

combatreform.org/squadsizeisnottheonlyproblem.pdf

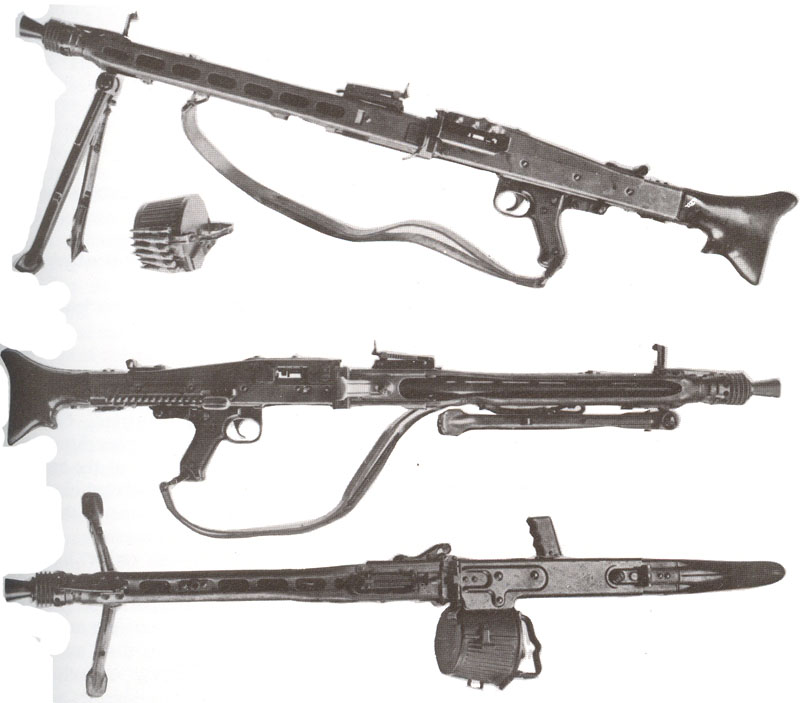

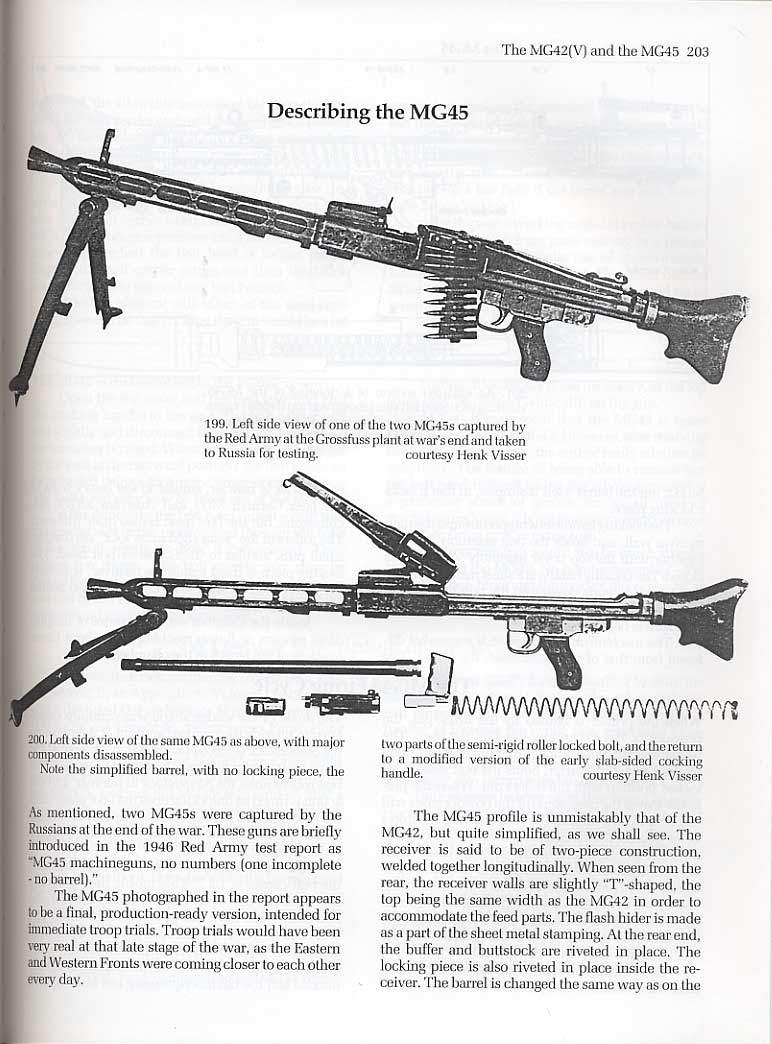

MG-42 Sustained-Fire Light Machine Gun?

Lighter weight MG45 made at war's end

The American infantry has suffered without a LMG in the squad all throughout WW2, Korea, Vietnam, Dominican Republic, Grenada, Panama--that's right its a problem that continues to today! You may say, "wait a minute! what about the M60 and the M249 squad automatic weapon? They both have got a pistol grip, bipod, are belt-fed and can change barrels for sustained fire"

Last Version of the M60: Still Not Reliable Enough

Sadly, both the medium-heavy M60 and light M249 are prone to jamming AKA "stoppages". The M60 at 23 pounds--is not light and was carried in machine gun squads at company-level; not in rifle squads.

M249 LMG: Jam-prone, 5.56mm bullets weak

True, the MG42 at 26 pounds wasn't "light", either--but it was/is reliable. The M60 needs a plastic ammo box (PAB) to compensate for its weak belt-pulling action, but the dumb U.S. military didn't buy them in bulk, so these guns continue to jam.

We eventually replaced and are replacing them with the heavier (27 pounds) but more reliable M240B--though this gun is still too heavy to be carried in the rifle squads who must be able to fire & maneuver. The tiny 5.56mm bullets the M249 shoots do not intimidate nor suppress the enemy. That's just the way it is. This is why the U.S. Army is replacing M249s with the 7.62mm Mk.48 light machine gun based on the more reliable M240 medium machine gun action.

Mk.48 7.62mm x 51mm NATO Light Machine Gun

Past is Prologue...

Before leaving "the greatest generation" off-the-hook, was there a way to fix the M1918 BAR to make it into a LMG capable of sustained fire? Did we have to wait 6 decades for something the Germans had all along?

The answer you will see is YES, so there's no excuse why these improvements were not made back in the 1930s--before WW2 even began.

Pistol Grip on the BAR?

BAR with pistol grip and Cutts compensator

First, the pistol grip; the American FBI realized this right away and added them to their Monitor BARs with a Cutts compensator on the barrel end to ward off muzzle climb. These machine guns were used to ambush and gun down gangsters Bonnie & Clyde.

Polish BAR with pistol grip

The Poles, Swedes and Belgians all added pistol grips to their BARs. The stupid American Army and marines in love with deer hunting rifles did not until after losing thousands of men in WW2 and Korea due to being ambushed and losing on the draw.

Quick-Change Barrel on the BAR?

Why not modify American BARs to have a quick-change barrel and carry case for an extra barrel--like the Swedish/Belgians BAR versions and Army employed?

www.youtube.com/watch?v=WxrSPmUkIEY

www.youtube.com/watch?v=WxrSPmUkIEY

http://home.comcast.net/~sfischer397/swedishbar/index.htm

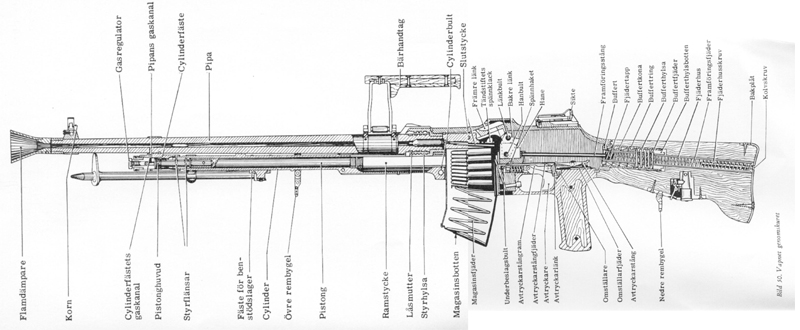

Swedish BAR with pistol grip and Quick-Change Barrel

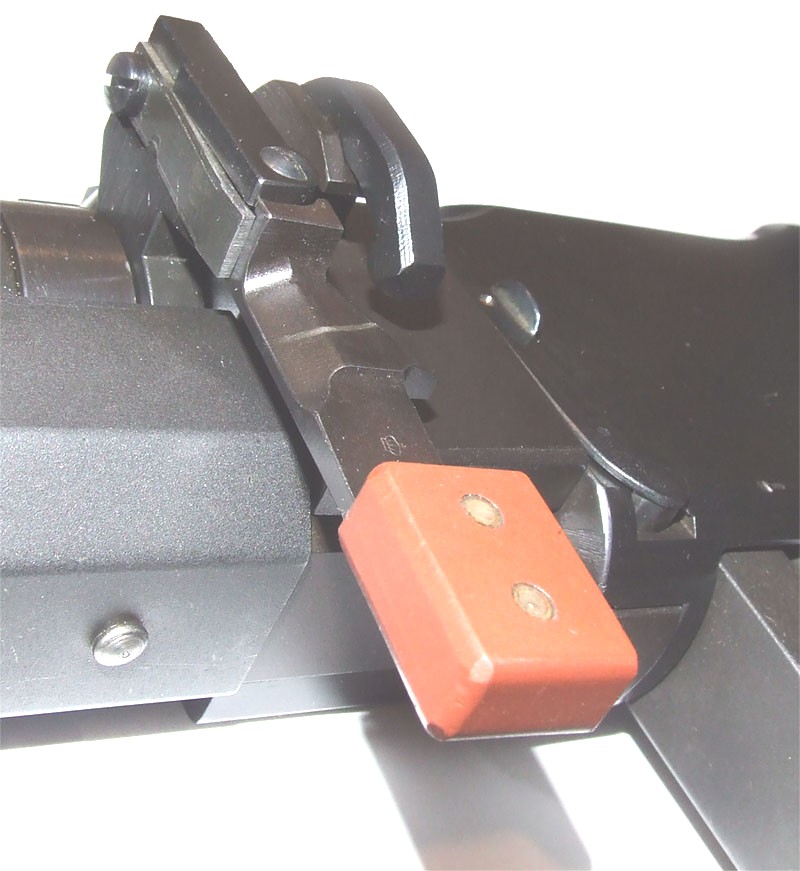

In 1935, the Swedes came up with a clever solution to modify the BAR for quick-change barrels. The Swedes added a quick change mechanism on to the front of the receiver that utilized the existing receiver barrel threads. The new quick change barrel would slide inside the new mechanism and would lock into place via and interrupted thread. The cleverness of the design allowed existing m/21 BARs to be converted to the new quick change arrangement. The change was officially adopted as the Kg m/37 and Carl Gustafs began production of this type. Many of the existing Kg m/21 BARs were converted to m/37 (as was mine). Production of Kg m/37 BARs totaled 15,398 when production ceased in 1944.

Belgian BAR with pistol grip and Quick-Change Barrel

In 1932, Belgium adopted a new version of the FN Mle 1930 allocated the service designation FN Mle D (D-Demontable or "removable") which had a quick-change barrel, shoulder rest and a simplified take-down method for eased cleaning and maintenance. The Mle D was produced even after World War II in versions adapted for .30-06 Springfield and

YOUTUBE channel owner "Mongo63a" shows how this was done.

http://home.comcast.net/~sfischer397/swedishbar/qcb.htm

The Swedes modification to the standard BAR receiver is very ingenious. It corrects one of the main complaints about the BAR when it is used in the Squad Automatic Weapon (SAW) role, that of not having a quick change barrel. This way when the barrel gets hot it can be changed for a spare cool one.

Barrel changes are easily made by:

1. Bolt cocked back on the sear.

2. Rotate the barrel release lever from the 3 o'clock position to the 6 o'clock position.

3. Lift the barrel release lever until it reaches its stop.

4. Grasp the barrel carry handle and push forward while holding onto the gun and remove the barrel.

5. To install the barrel reverse the procedure.

What about a drum for the BAR like the MG42 had?

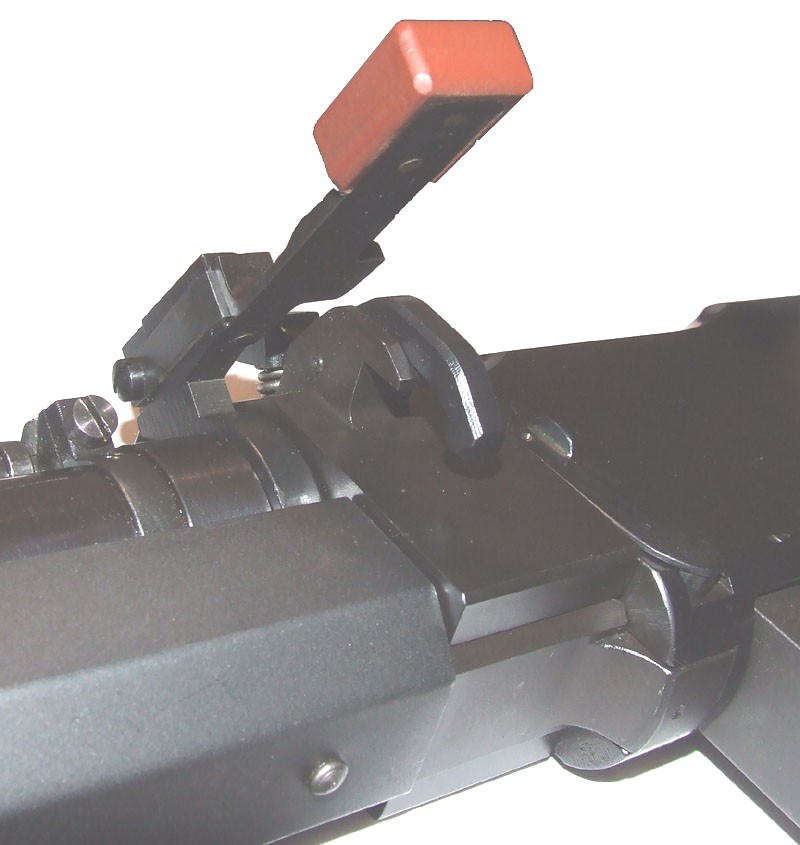

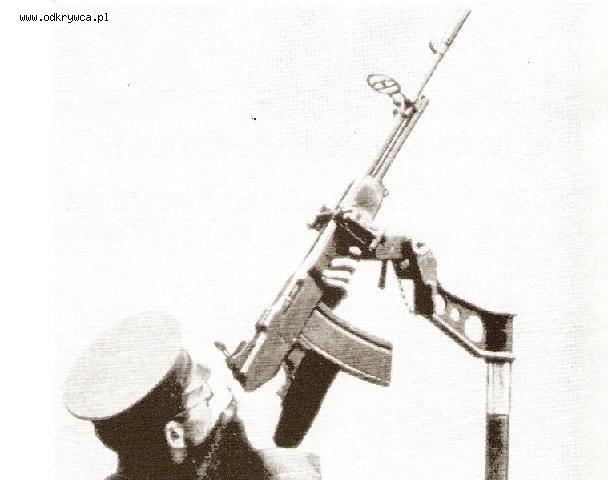

The Polish Air Force had them!

Polish Air Force BAR with 91-round pan magazine

http://en.wikipedia.org/wiki/M1918_Browning_Automatic_Rifle

http://en.wikipedia.org/wiki/Karabin_maszynowy_obserwatora_wz.37

www.weu1918-1939.pl/lotnictwo/inne/szczeniak/dowodztwo_lotnictwa_inny_sprzet_szczeniak.html

Sustained fire was practically impossible with the standard 20-round box magazine thus a new feed mechanism was developed, which was added to the receiver as a module. It contains a spring-loaded bolt-actuated lever, which would feed a round from a 91-round pan magazine located above the receiver and force the round into the feed path during unlocking. The machine gun was accepted in 1937 and ordered by the Polish Air Force as the karabin maszynowy obserwatora wz. 1937 ("observers machine gun model 1937"). 339 machine guns were eventuality acquired and used as armament in the PZL.37 Łoś medium bomber and the LWS-3 Mewa reconnaissance aircraft.

I'm not saying we should have adopted the Polish pan magazine for our infantry BARs--only that IT WAS POSSIBLE to feed it more than 20 rounds at-a-time. It seems clear that had we put our minds to it some clever engineer like the people at today's MWG who make 90-round snail drums for the M16/M4, could have been tasked to do the same for the BAR to give it a sustained fire capability at least at the beginning of the firefight. By having the 20-round magazine underneath the action, the BAR didn't have much space to work with, but did anyone try to see if a 30-round magazine wouldn't be too long for prone firing? A snail drum magazine of say 50 rounds would have curved up and away from under the action to preserve ground clearance.

Polish BAR with 40-round magazine for Anti-Aircraft Use

CONCLUSION: the U.S. Army was not alert and on-the-ball to improve itself even back in WW2--when the pressure was on! The marines being asleep is no surprise, either. The American penchant for smugness and complacency over our own BS is legendary. What were our military attaches' doing overseas when they saw our allies make these improvements? What were they doing while Europe was being over-run by German squads with MG34 and later MG42 LMGs?

What about a Bren LMG Shooting American .30-06 [7.62mm x 82mm] Ammo?

While its true BARs could be made to have QCBs, it couldn't use 30-round magazines like the Bren LMG which had them on top of the action instead of underneath. Brens also had 100 round drums to enable sustained fire.

The British infantry shot RIMMED .303 caliber and the Americans RIMLESS .30-06....

www.btinternet.com/~ian.a.paterson/equipinfantry.htm

It gets stranger. The British Bren LMG originally shot German RIMLESS 7.92mm and used BESA LMGs in their tanks, yet did not mass-produced Bren LMGs in the logical rimless cartridge that they could use captured German ammo against them. They made their Sten SMG shoot 9mm from German MP40 SMGs....

You have to load rimmed .303 cartridges carefully to stagger them sequentially:

http://en.wikipedia.org/wiki/Bren_light_machine_gun

The 30-round magazine was in practice usually filled with 27 or 28 rounds to prevent jams and avoid wearing out the magazine spring. Care needed to be taken when loading the magazine to ensure that each round went ahead of the previous round, so that the .303 cartridge rims did not overlap the wrong way, which would cause a jam. A 100-round drum magazine was available for the Bren for use in the anti-aircraft role.

www.btinternet.com/~ian.a.paterson/equipinfantry.htm

The Bren was an excellent light machine gun, being simple, strong, accurate and easy to fire. It was remarkably free from stoppages and other vices. It was a gas-operated weapon, using a long-stroke principle. The barrel was removable and locked to the body by a quick release nut. The gas block was on barrel and mated with the gas cylinder, which is below the barrel, but the block could be drawn outwards. Changing the barrel was both quick and easy, as the carrying handle is on the barrel, thus reducing the risk of burns. It was recommended that the barrel be changed every three magazines to allow the hot barrel to cool beside the gun. The gas cylinder had a long piston inside which ran back in the body and carries the return spring. The breech block rides on the piston extension and locked by tipping its rear end into contact with lugs on the body. Apart from the trigger mechanism there are few other working parts.

The magazine held 30 rounds and fed vertically downwards, and thus the sights were offset to the left side. The magazine was one of the weak points as it was essential that each round be fed in with its rim behind the one on front. Failure to do this with even one round caused a stoppage, though easily cleared. The magazines were also sensitive to damage, which could also cause a stoppage. Apart from this virtually the only other thing to break on a Bren Gun was the occasional firing pin.

British Light Bicycle Machine Gunner

Copying the MG42 in American .30-06 [7.62mm x 82mm] Ammo?

www.perthregiment.org/rperth3.html

Queen's Own Riflemen (3CID) manning a defensive point with a captured German MG42, Bretteville-Orgueilleuse, France, 20Jun44. One Soldier has a bandoleer tied around his waist, a common method of carrying ammunition when in defensive positions. (LAC, PA190896)

What about copying the MG42 to shoot American .30-06?

We tried it and botched it.

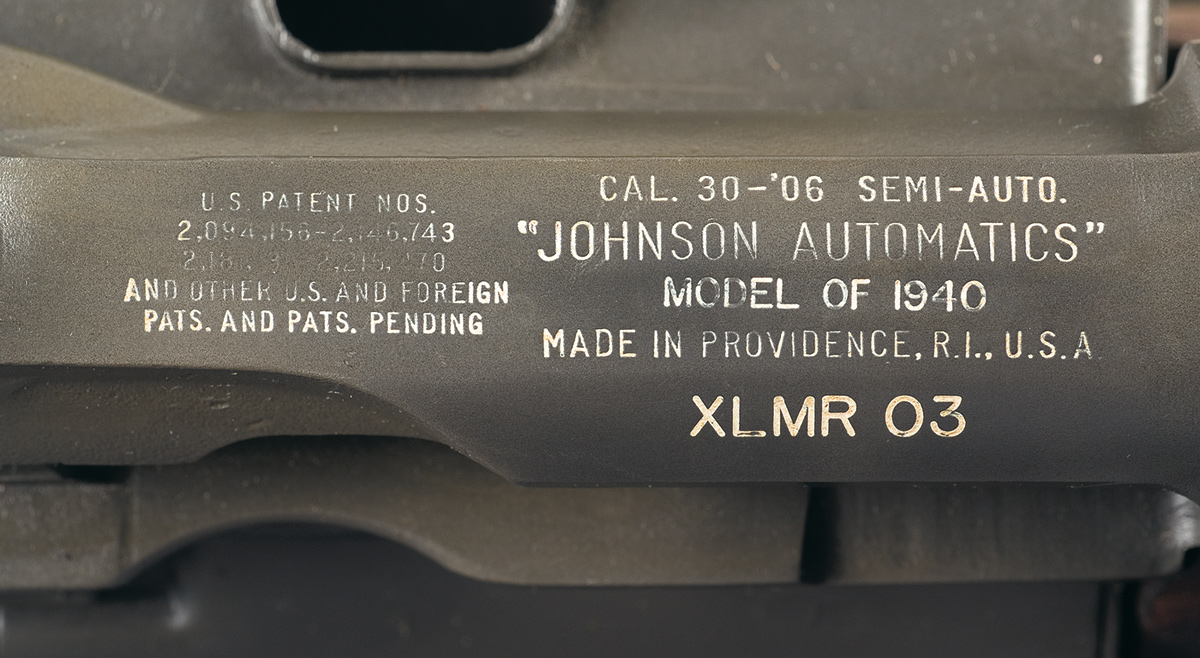

Was the M1941 Johnson Semi-Automatic Rifle & Light Machine Gun Better than the M1 Garand SAR & BAR?

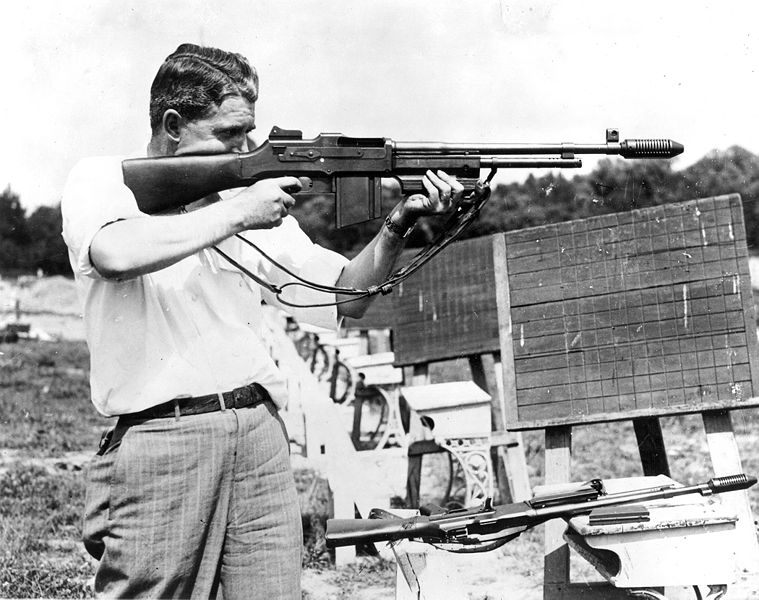

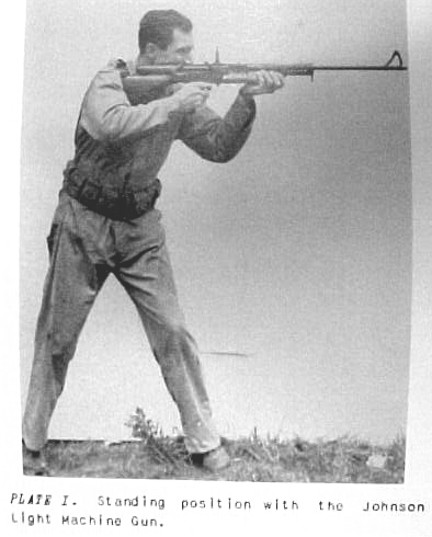

1st SSF Paratrooper with Johnson LMG

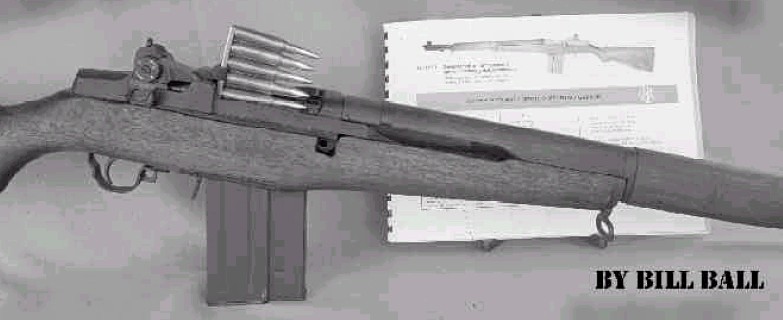

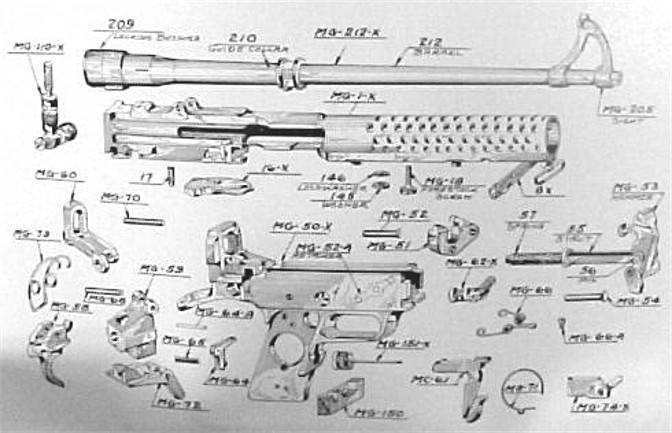

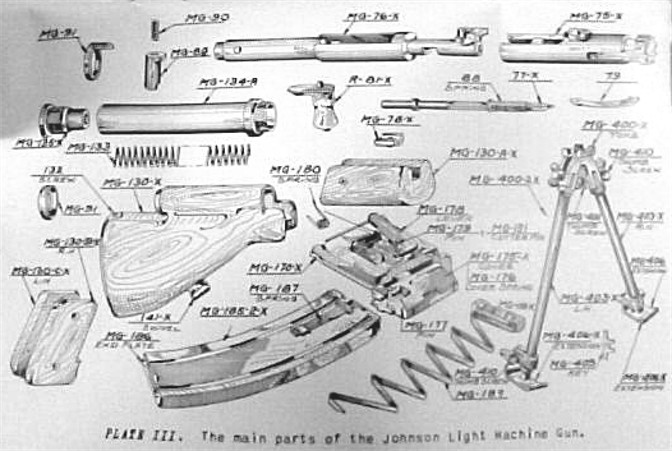

Credit has to be given to marine reserve officer Melvin Johnson for trying very hard to give our infantry technotactical supremacy with his innovative weapons. He was up against a deer hunting rifleman-loving bureaucracy that didn't then (and still doesn't) accept modern war realities that automatic weapons and high explosives (HE) effects dominate battlefields. Johnson seemed to understand this and did something about it. His 25-round magazine-fed Johnson LMG had a quick-change barrel (QCB) to enable sustained fire to suppress enemies--and many design features we need to incorporate today in a "M16A5" assault rifle--like stripper clip loading and ability to switch types of cartridges it can shoot.

combatreform.org/21stcenturyrifle.htm

combatreform.org/thunderrun.htm

The Johnson LMG's Sten SMG-style side magazine attachment is also a clever way to avoid the ground clearance problem without adding to your silhouette by a top-attached magazine like the British Bren LMG had.

Johnson Internet board member "gyrene" on August 10, 2006 sums up the Johnson SAR-LMG vs. M1 Garand-BAR situation best:

www.gunandgame.com/forums/powder-keg/32929-how-often-you-see-one-these.html

Johnson

Trey45 - Hmmm, My M1941 Johnson shoots very well. The only malfunction, is that occasionally it will double, which I have not had happen to me, but others firing it had it double about 5 different times, while I was present.

Many semi-auto rifles have what some call a "Sweet Spot", where the trigger will function with only a slight movement of the trigger (from the recoil), and this is the suspected gremlin that jumps up after the first round fires.

There is a "Hard Corps" of people that have absolutely no use (they hate it and really don't know anything about it) for the M1941 Johnson, and will relate many kinds of horror stories about them. Maybe more horror stories than there were M1941 Rifles built. I have seen and fired as many as 75 Johnson M1941 Rifles, and I have not seen more than just a few malfunctions (maybe as many as 10, counting the 5 times my own Johnson M1941 has doubled)!

There were only about 20,000 of them built (maybe less, because the records are not too comprehensive (at least vague)), which were built under contract to the Dutch Government. Not all were delivered by the time the Dutch Government had moved to England, and some of the remaining deliveries were made to the Dutch in Indonesia, for use against the Japanese. Some of these ended up in the hands of the Chinese Communists, and were used against U.S. G.I.s in Korea.

The M1941 Johnson rifle was designed and built for far less money than was used for the development of the M1 Garand (which was its competition). In fact it could be built in any well-equipped machine shop (one of its features), thus it required no single location (such as Springfield Armory) which was the M1 Garands' biggest handicap, at first.

The M1941 Johnson SAR was "tested", a few times against the M1 Garand, by the people who were responsible for building and delivering the M1 Garand, and each time it was considered nearly equal to the M1 Garand, and so it was dropped as a consideration. Keep in mind each of these "tests" were performed by a literally unchanged M1941 Johnson, against a constantly changing M1 Garand (such as the development to remove the "Gas Trap" system and switch to the "gas port" system used on the M1 Garands we now know and love)! These costs were enormous for the M1 Garand development, to keep it on par with the M1941 Johnson. The total development costs for the M1941 Johnson were less than the cost for changing the M1 Garand from a "Gas Trap" to the current "gas port" system.

Another Johnson development was the Johnson Light Machine Gun. It was issued to some of the marines along with some M1941 Johnson SARs in 1942. Remember it was mid to late 1943 before the marines were receiving enough M1 Garands to make a difference. Some marines had traded their war trophies on Guadalcanal to Soldiers for their M1 Garands, but that began happening when some units of the U.S. Army were relieving the 1st marine division on Guadalcanal, in 1942, for the USMC to prepare for the next assault on the Japanese with other Army units.

The marines did not want to give up the M1941 Johnson, or the Johnson Light Machine Gun. The high brass did not want the U.S. Army logistics system cluttered up with rifle parts that were not useable on the M1 Garand, (and it wasn't invented here {NIH}, Springfield Armory, Springfield, MA} THANK YOU VERY MUCH! The Johnson Light Machinegun was also used by the 1st Special Service Forces in Italy against the Germans, and the 1st Special Service Forces did not want to give them up. This seems to be a common thought by those that used the JSAR (M1941 Johnson Semi-Auto Rifle), and the Johnson LMG, in combat.

The Johnson Light Machinegun was a 12 1/2 pound machine gun with a 25-round magazine, that Melvin Maynard Johnson demonstrated many times firing it with one hand, held up in front of him. The Johnson Light Machine Gun fired the .30-06 cartridge, the same as the M1 Garand, the .30 Cal Browning Machineguns, and the BAR (Browning Automatic Rifle). It would have been competition for the BAR, had it been selected as a standard issue weapon. As compared to the BAR, the Johnson LMG weighed 12.5 pounds, the BAR weighed 20 pounds; the Johnson LMG had a 25-round magazine, the BAR had a 20-round magazine; the Johnson LMG could be held and fired with one hand, the BAR always required two hands; the cyclic rate of fire for the Johnson LMG was 600 rounds per minute (which could be slowed down), the BAR cyclic rate was single shot and (correct me if I'm wrong) about 350 or 500 (selectable), and many other comparisons where the Johnson LMG was superior to the BAR. I used the BAR and I liked it very much! I do regret never getting the opportunity to use the Johnson LMG.

The Johnson LMG was also built with the same receiver as the M1941 Johnson SAR; with the bolt and trigger group differing to allow for selectable semi-auto or full auto firing.

The Johnson Semi-Automatic Rifle M1941 could change calibers easily, by simply removing the barrel (I've done a thousand times, it takes about 15 to 20 seconds), and installing another barrel. It had barrels with various calibers built for it, and it could fire 7.7 Japanese, 7 x 57mm Mauser, 8 x 57mm Mauser, and any other that are near the same size cartridges. It could be loaded with a standard 5-round stripper clip, or load a single cartridge at a time, into a 10-round magazine (topping it up using a 5-round stripper clip, or a single round with the bolt open or closed was a normal activity).

If you see a Johnson SAR at the range, ask the owner about getting a demonstration, I do a demo quite frequently, and offer shooters a chance to shoot a real rarity. They are always amazed at the light recoil as compared to the M1 Garand, especially since they both shoot the same ammo. On that note, the M1941 Johnson can use M1 Ball or M2 Ball, and the M1 Garand cannot shoot the M1 Ball without endangering the M1 Garand and the shooter. M2 Ball was designed for the M1 Garand, but can be fired in the Browning Machine Guns, the BAR, the 1903/1903A1-A3-A4, and the M1917.

M1 Ball was the .30-06 cartridge designed for the M1903 Springfield. The .30 Cal Browning Machine Gun and the BAR were designed to use M1 Ball, which gave the machine guns a range of 2,500 yards, and the volley fire capability of the M1903 Springfield's a range of 2,000 yards. M2 Ball cuts that range down to between 2,000 to 2,200 yards for the machine guns and 1,500 to 1,800 yards for the M1903 Springfield in volley fire mode.

Dpon't think for a minute that I do not have a love for the M1 Garand, and the BAR, they are both excellent for their intended applications. However, I think that the people who prevented the M1941 Johnson SAR and the Johnson LMG, from being alternate issue weapons, did the U.S. a disservice.

Had the M1941 Johnson been declared an alternate issue, and been produced, the U.S. marine corps would have had a semi-auto rifle at least a year before they began receiving the M1 Garand, and the Johnson LMG would have been much more manageable in the Pacific Theater than the BAR. The Johnson products could have been manufactured in many locations throughout the U.S., whereas the M1 Garand and the BAR were manufactured in the heart of the gun manufacturing industry in Massachusetts, and Connecticut, leaving the U.S. open to a possible single episode of sabotage, which could have interfered with the war effort!

Fix the Bayonet Attachment Problem?

The main problem with the Johnson LMG and its rifle cousin is their barrels move and they cannot have bayonets attached to them without causing the weapons to malfunction and jam. So why not add a lightweight aluminum bar under the Johnson LMG to attach the bayonet and leave the barrel alone? Bayonets ARE important: combatreform.org/bayonets.htm

Develop a Double-Stack Magazine or Snail Drum?

Couldn't a double stack magazine to double ammunition from 25 to 50 been created that narrows at the top to fit into the Johnson LMG action? How about a snail drum to hold 50 rounds?

Assault Rifle Version of the Johnson LMG?

The M1941 Johnson rifle is innovative in that 5-round stripper clips can be feed into its rotary action as you go along.

Johnson

The rotary action held 10 rounds so you'd stripper clip feed twice to get full. If you shot up half of this, you could load another 5-round stripper clip to top off, or even top-off with individual cartridges. On the M1 Garand, you load a 8-round en bloc clip into the action and are stuck with 7-6-5-4-3-2-1 rounds--until you go completely dry and load another en bloc of 8 into it. In other words, you cannot top-off rounds like with the M1941 Johnson. However, you can also top-off rounds with the Johnson LMG into its detachable magazine, so why not make an assault rifle version of it, instead?

Why not make a bipod-less, firing-from-the-closed-bolt-only, lightweight assault rifle version of the Johnson LMG and then everyone shoots from the same 25-(company brochure says 25 not 20) round magazines and 5-round stripper clips? The Johnson LMG is listed as 13 pounds empty. Get that weight down to under 8 pounds and you've got a war-winner!

Guess what? Johnson did it!

www.rockislandauction.com/viewitem/aid/50/lid/3512

What About the Germans? They Came to the Exact Same Conclusions--and FIELDED Assault Rifle-Light Machine Guns with their elite' Fallschirmjaegers

http://en.wikipedia.org/wiki/FG_42

A report on the new German 7.92-mm automatic rifle for paratroopers, the F.G. 42, from Intelligence Bulletin, June 1944.

[Editor's Note: The following article is wartime information on enemy equipment and tactics published for Allied Soldiers. More accurate data on German equipment and tactics is available in postwar publications.]

NEW GERMAN RIFLE FOR PARATROOPERS

-----------------------------------------------------------------------------

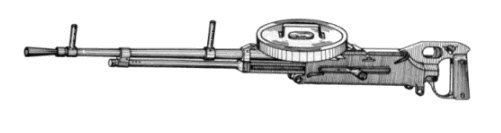

The Germans have a new 7.92-mm automatic rifle, the F.G. 42 (Fallschirmjäger Gewehr 42), which is a light and versatile weapon, especially suitable for use by German airborne personnel. It should be remembered that the 9-mm machine carbines (M.P. 38/40), which are now in general use, were originally introduced as parachutists' weapons; in like manner, the Germans may well put this new 7.92-mm rifle to more general use in the future.

The new rifle (see figure), which represents a departure in small-arms design, is a close-combat weapon firing any 7.92-mm Mauser rifle ammunition, and combines a relatively light weight [1] with a reasonable degree of accuracy both in single-round and automatic fire. The Germans have struck a balance between the weight limitations of the machine carbine and the power and pressure requirements of the rifle or light machine gun.

New German Paratrooper's Rifle

The F.G. 42 is air-cooled and gas-operated. In spite of the extensive use of stamping, instead of intricate machine-tool work, and in spite of the fact that all component weights have been reduced to a minimum, the new weapon is fairly sturdy.

It is provided with a light folding bipod and a spike bayonet which, when attached, increases the over-all length of the rifle from 3 feet 1 inch to 3 feet 8 1/4 inches. The feed is from a 20-round box magazine which fits into the left side of the gun. The magazine may be loaded separately or from standard 5-round Mauser clips from the right side of the gun.

The F.G. 42 may well be used as a "powerful" machine carbine, as a "short range" self-loading rifle, or as a light machine gun when mounted on the bipod.

1. The F.G. 42 weighs 10 3/4 pounds with the bayonet and with a filled 20-round magazine.

Improving the M1 Garand--Did We Think Of It? What's Holding Us Back Now?

Eventually the "M1 Garand Sr." became the "M14 Garand Jr." with Detachable box magazines and top-load from stripper clips--it could have been this way from the get go

American ordnance stupidly rejected detachable 20-round magazines for the M1, so Garand defaulted back to the 8-round en bloc. Their absurd excuse was that the magazines would get lost and somehow get in the way of "From Here to Eternity" BS parade ground drill & ceremony. FYI, if you want to be a fucktard and do D&C there is nothing stopping idiots from removing the magazine (imagine that) so you can do left and right shoulder, arms all day long with today's M16s, M14s or a M1 Garand had it been loaded by detachable magazines. The tragedy is BAR magazines could have been shared by both automatic riflemen and riflemen to great effect in WW2.

WW2 Japan Copies--and Improves the M1 Garand Shooting from 10-Round Stripper Clips

http://nramuseum.com/the-museum/the-galleries/ever-vigilant/case-63-world-war-ii-allies-and-japan/%27%27japanese-Garand%27%27-wwii-semi-automatic-rifle.aspx

Japan's wartime production of semi-automatic rifles was restricted to experimental and prototype models. Shortly before the war's end, the Imperial Navy produced the Type 5 rifle, a 7.7mm caliber copy of the American M1 Garand which featured a 10-round box magazine rather than the M1's 8-round en bloc clip. These were also manufactured in extremely limited numbers; perhaps as few as one hundred were produced. Limited resources and shortages of suitable arms caused some of the earlier prototypes to be committed to combat. Assembly number 58 on minor parts.

Arisaka-type bolt-action rifles served as the mainstay of Japanese infantry troops during the Second World War. These arms trace their origin to 1897, when a commission headed by Tokyo Arsenal superintendent Colonel Nariaki Arisaka developed the Type 30 rifle to address deficiencies of the Murata Type 13 11mm caliber single-shot and Type 22 8mm caliber tubular magazine military rifles then in use by Imperial forces. The Type 30 rifle, so designated because it was adopted in the 30th year of the reign of Japan's Emperor Meiji, utilized the Mauser turning bolt mechanism and was the first Japanese rifle to chamber the 6.5mm caliber smokeless cartridge. These rifles were adopted as Japan's standard service rifle and were the principal arm used by Imperial troops during the Russo-Japanese War of 1904-05.

Minor modifications to this design yielded the rare Type 35 rifle, introduced in 1902. The Type 38, which followed in 1905, employed the one-piece turning bolt mechanism and five-round staggered-column non-detachable box magazine of the German Mauser Model 98. Unlike the German rifle, these arms cocked on forward movement of the bolt, a feature common to British military rifles. Type 38 bolts were hand-fitted, which produced an extraordinarily smooth pull. This feature increased the workload of ordnance technicians who were required to repair and maintain them, as bolts were not interchangeable. These rifles chambered a 6.5mm caliber semi-rimmed cartridge and featured extremely strong actions with locking lugs, gas ports, and shields which effectively contained and diverted exhaust gasses from ruptured cartridges with little or no resulting damage to the receiver and associated mechanisms. Post-Second World War tests showed that the Type 38 action was of superior strength to the Mauser, and to the U.S. Model 1903 and 1917 rifles.

The design of Type 38 arms differs from the Mauser in the action of their safety mechanism, which consists of a large rotating knob on the rear of the bolt rather than the Mauser's tab-style rotating safety. These and later Japanese rifles also feature a sliding bolt cover similar to that used by Britain's Lee-Metford rifle. Although useful for keeping foreign matter out of the chamber, covers were generally removed by troops in the field to reduce noise. These rifles also featured a graduated rear sight and a two-piece mahogany pistol-grip butt stock, which served both to strengthen the grip and to conserve materials as the Japanese had difficulty in obtaining blanks of suitable size for one-piece stock construction. Beginning in the 1930s, both the bore and bolt face were chrome-plated to prevent corrosion and to reduce wear.

The Type 38 was produced in long rifle, short rifle, and carbine variants. Included were standard models with bayonet lugs, and the Type 97 rifle, a sniping version of the Type 38 with a turned-down bolt handle and wire monopod, which made its debut in 1937. Carbines included a hinged/folding buttstock version for use by airborne troops, and the Type 44, which was introduced in 1911. These were essentially identical to the Type 38 carbine but with the addition of a permanently-attached folding bayonet, Type 38 rifles served with Japanese troops from 1907 through 1945. These arms saw limited action with Japanese troops during the First World War, and were used extensively throughout the Second World War. In addition, many were purchased by other nations including Britain, Imperial Russia, Mexico, Brazil, and Siam as training and as primary- or secondary-issue arms. Some of these are chambered for other cartridges and bear the crests of the purchasing nation on the receiver in much the same way as Mauser rifles produced under license outside Germany.

In addition to the Type 38 and its variants, the Imperial Navy also possessed about 60,000 6.5mm Type "I" rifles which had been produced in Italy both by Beretta and at government arsenals. These arms are seldom encountered today, and little is known about them. Similar to the Type 38, the Type "I" combined the Japanese-type two-piece stock with a Mannlicher Carcano action and Mauser-type magazine. These arms saw action in the hands of Japanese Naval infantry who opposed the U.S. 4th Marine Division at Kwajalein Atoll in 1944. Japanese troops were also armed with Manchurian-produced Mausers, as well as with Czech Vz24 rifles that had been captured when Nazi troops occupied Czechoslovakia. Captured American and British .30 caliber rifles were used to arm garrison troops. Japan's wartime experience in China and Manchuria during the 1930s provided the impetus for development of a larger-caliber military rifle, as the 6.5mm (.25 caliber) cartridge was outclassed by the Chinese 7.9mm Mauser. Several designs based on the Type 38 but chambered for a 7.7x58mm caliber rimless cartridge, roughly equivalent to the U.S. .30 caliber military cartridge, were introduced for testing.

Field trials brought about the 1939 adoption of the Nagoya Arsenal-designed Type 99 rifle, which took its name from the Japanese calendar year of 2599. The Type 99 was slightly shorter than the earlier Type 38 and included a folding wire monopod, a hinged magazine floorplate, side-mounted sling swivels, and an graduated rear sight equipped with folding arms which could be used to defend against air attack. The standard Type 30 bayonet could be mounted to the Type 99, as could a grenade launcher. These rifles first saw limited action during the Solomons Campaign of late 1942, and by the Aleutians campaign, entire Japanese regiments were equipped with the new arm. Although they never replaced the Type 38 rifle, the Type 99 was used to a greater degree as additional copies became available.

As with the earlier Type 38, these rifles were produced in both long and short rifle, sniper, and carbine versions, as well as a take-down version, designated the Type 2, which was used by Japanese paratroops. Sniper variants employ a 2.5- or 4-power fixed-focus telescopic sight mounted to the side of the receiver. While standard-production rifles feature bolt handles that extend at a right angle to the body of the rifle, bolt handles on sniper arms are bent downward to allow them to function without interference from the offset-mounted scope. The Type 2 paratroop rifle employs a screw fastener and a sliding wedge/dovetail assembly below the receiver ring to secure the barrel and fore-end to the receiver/stock assembly.

Arsenal pressure test guns were produced for use in ammunition development and for quality control purposes during the manufacturing. These are extremely rare today. Smoothbore training rifles, patterned after both the Type 38 and Type 99 service rifles but which used special cartridges, were also produced. These are often identifiable by the lack of markings on the receiver and by their crude finish, although these same characteristics may also be observed on late-war "last ditch" production arms. Trainers also lack the gas port and front locking lugs common to standard service rifle bolts.

Japanese military rifle production was restricted to government arsenals. The Type 99 was manufactured at the Tokyo, Kokura, and Nagoya Arsenals, and at various arsenals in Osaka, Fukushima, and Hiroshima. Rifles were also manufactured under Japanese supervision at Mukden Arsenal in Manchuria, and at Jinsen Arsenal in Inchon, Korea. Production was carried out with much of the same equipment as that used to manufacture the Type 38. To conserve resources, simplify production, and reduce costs, forged and machined components were replaced with metal stampings where possible. Further cost-cutting measures were introduced in 1943, when the Type 99 rifle was produced without a cleaning rod, bolt cover, sling swivels, monopod, or a chrome-plated bore, and with fixed rear peep sights and a wooden butt plate. Earlier rifles featured front sights with protective "ears", but even these were eliminated late in the war. Unlike the Type 38, the action of these late-production rifles was of inferior strength and construction, a situation that only worsened with the declining fortunes of Japan's military forces and the corresponding increase in American aerial bombardment of industrial centers. In some cases, desperate Japanese munitions-makers even resorted to producing rifles with cast-iron receivers. Consequently, Type 99s manufactured near the end of the war were extremely suspect and could, under adverse conditions, be equally if not more dangerous to its Japanese user as it was to Allied troops. This situation is not indicative of the quality of earlier-production rifles, which were well-designed, quite reliable, and very effective in combat. Even in better times, however, the Type 99 was not as well-made as its predecessor.

At the start of the Second World War, the United States was the only country that produced a semi-automatic rifle as its standard infantry arm. The Japanese Army had been evaluating semi-automatic rifle designs as early as 1931, when the Nambu Rifle Manufacturing Co. received a contract to design and test both a semi-auto rifle and light machine gun. Nambu produced several designs, none of which were satisfactory. During this period, two 6.5mm caliber gas-operated semi-automatic rifle designs were introduced, both of which were based on foreign models. Both the Army's Tokyo Arsenal and Nippon Special Steel Co. produced experimental rifles based on the American J.D. Pedersen-type toggle action, and a rifle patterned after the Czech ZH-29 was produced by Tokyo Gas and Electric. The Japanese Pedersens suffered from the same cartridge-feed problem as their American-designed cousins, and the ZH-29s proved to be inaccurate.

Japan's interest in semi-auto military arms waned due to their increased cost over comparable bolt-action rifles, the inability of Japanese industry to manufacture sufficient supplies, and a belief among conservative military officers that semi-automatic rifles were wasteful of ammunition. The outbreak of war in China during 1936 increased demand for the Type 38 rifle, and as military production took up available resources, the semi-automatic rifle program was shelved until 1941.

As the war progressed, other nations followed America's lead in developing and adopting semi-automatic rifles, but Japan's production of these arms continued to be restricted to experimental and prototype models. Shortly before the war's end, the Imperial Navy produced the Type 5 rifle, a 7.7mm caliber copy of the American M1 Garand which featured a 10-round box magazine rather than the M1's 8-round en bloc clip. These were also manufactured in extremely limited numbers; perhaps as few as one hundred were produced. Due to limited resources, the Type 5 quite likely would never have entered production even if Japan had managed to prolong the war. Shortages of suitable arms caused some of the earlier prototypes to be committed to combat, including two Pedersen-type rifles that were captured by American troops on Okinawa.

All Japanese armament production ended with the country's surrender in August 1945. Occupation troops destroyed all production equipment and tools and confiscated all military arms. The Imperial seal was ground off of the receivers of captured arms, with some sources indicating that this was done under order of General Douglas MacArthur, while others claim that the Japanese received permission to remove the chrysanthemum prior to surrendering them to Allied troops.

Based on the presence of absence of these seals, Japanese military rifles may be identified either as captured in combat or as post-war surrendered arms. Many captured rifles were later used by Chinese, Korean, Vietnamese, Burmese, and Indonesian troops, while others were brought home as war trophies by returning Soldiers and marines. Total production figures for Arisaka 6.5mm and 7.7mm rifles are unavailable, but estimates run as high as 10 million, including those manufactured for export.

M1 Garands Were Supposed to Shoot 20-Round BAR Magazines All Along! (and load from stripper clips).

www.lonesentry.com/articles/fg42/index.html

"New German Rifle for Paratroopers" from Intelligence Bulletin, June 1944

We didn't have to wait for the BM59 or the M15 in the 1950s...

http://forums.gunboards.com/showthread.php?83122-M1-Garand-Magazine-conversion

Honestly at the time the U.S. Army Ordnance published their requirements for a semi-automatic rifle they didn't want a box-fed magazine infantry rifle. In fact their exact words were that "a detachable magazine was acceptable--but not desirable". If you were a weapon designer and read that; what kind of rifle would you send to the Ordnance Department dinosaurs? If you go back and study the history of the U.S. Army's quest for reliable semi-auto rifle you will see they were very concerned about Soldiers wasting ammunition. Not only that, but a rifle with a magazine would be more expensive as Soldiers would loose them. Also remember the big selling point with the M1941 Johnson was that it didn't have a magazine nor a clip and its integral rotary magazine could easily be topped off by single rounds and the commonly available stripper clips. Hell, even the FN-49 had a non-detachable magazine and by then it was clear to a blind man that detachable magazines were the way ahead.Some of John Garand's early versions used detachable box magazines.

He switched to the en bloc clip when he saw which way the wind was blowing in regards to the military's preference for non-detachable mags.

I've heard that one of the reasons they didn't want a detachable mag is that they wanted a more "streamlined" rifle without a protruding mag so that it wouldn't mess up the "manual of arms." I've read that in a couple places, but have no way to know if it's actually true or not.

Garand was a smart guy. He not only designed the rifle, but the fixtures and machines to manufacture it as well. That's one of the reasons it was accepted is that it was developed with an eye toward manufacture all along, unlike many private designs that were submitted before then.

I remember there was a later variation of the Garand. It used hi-cap mags. I Just dug the article out of my closet. It was called the Beretta BM59. Chambered for .308 NATO.

Notice the Pistol Grip to Improve Assault Fire Speed & Accuracy

There are also a few prototype M14s floating around out there somewhere. The first attempts to improve M1 Garand were made during the Second World War, and numerous experimental modifications in .30-06 were built, mostly using the 20-rounds detachable magazines from Browning BAR M1918 automatic rifle. One of such prototypes was the T20 of 1944.The T20 was basically the M1 Garand rifle fitted with 20 rounds BAR magazine and with selective fire capability.

Source:

http://world.guns.ru/assault/as15-e.htm

www.thehighroad.org/archive/index.php/t-456179.html

Jim Watson

June 13, 2009, 06:52 PM

According to W.H.B. Smith, the 1944 - 1945 T20 rifles used modified BAR magazines. The magazine for the final T20E2 could be used in a BAR but the standard BAR magazine would not work in the T20E2. That rifle was not a converted M1, it was built on a new receiver designed for the removable magazine and selective fire. The Army ordered 100,000 of them for the invasion of Japan, (along with the 25,000 T26 "Tankers") but neither was delivered due to the atomic bomb and early VJ Day.

T20E2 Garand with Pistol Grip and Selective-Fire; no Magazine Attached

Remington worked on a similar rifle, the T22, of which Smith says: "...used a BAR magazine but were not too successful and it was decided a new magazine should be designed."

The original prototype Garand of 1920 had a box magazine that looks an awful lot like a BARs, plenty available to work with after WW I; but I have seen nothing to say whether it was modified or used as is.

Can You Top-Off M1 Garand 8-Round En Blocs?

So you are stuck with a M1 Garand shooting 8-round en blocs. You can and should upgrade to a pistol grip stock and have load bearing equipment to carry multiple en blocs. What about topping off rounds if you have shot a few?

www.biggerhammer.net/manuals/Garand/m1.htm

www.biggerhammer.net/manuals/Garand/tm9-1275.htm

Technique 1

www.youtube.com/watch?v=U8C0KdP6BdI

www.youtube.com/watch?v=U8C0KdP6BdI

www.biggerhammer.net/manuals/garand/op.htm

Chapter 3.

OPERATION AND FUNCTIONING

12. Loading the Rifle

(a.) Single round

. To load a single round, pull the operating rod all the way to the rear. While holding the muzzle below the horizontal, place a round in the chamber an seat it with the thumb. With a knife edge of the right hand against the operating rod handle, force the operating rod slightly to the rear. Push down on the follower assembly with the right thumb and allow the bolt to ride forward. Remove the thumb from the follower assembly and release the operating rod handle, allowing the operating rod to go all the way forward.(b.) Full clip. To load a full clip, hold the rifle at the balance with the left hand and pull the operating rod handle all the way to the rear. Place the butt of the rifle against the thigh or on the ground. With the right hand, place a full clip on top of the follower assembly. Place the thumb on the center of the top round in the clip and press the clip straight down into the receiver until it catches. Swing the right hand up and to the right to clear the bolt in its forward movement. Note that the operating rod is not held to the rear during loading since there is no danger of it going forward as long as pressure is maintained on the top round in the clip. It may be necessary to strike forward on the operating rod handle with the heel of the right hand to fully close and lock the bolt.

(c.) Partially filled clip. To load a partially filled clip, hold the rifle in the same manner prescribed for a full clip. With the operating rod all the way to the rear, place an empty clip into the receiver. Place the first round into the clip and on the follower, to the left of the follower slide. Press the second round into the clip, exerting a downward, turning motion until the round snaps into place. Load the remaining rounds in the same manner. With the knife edge of the right hand against the operating rod handle force the operating rod slightly to the rear. Push down on the top round with the right thumb, allowing the bolt to start the top round forward. Remove the right hand and allow the operating rod to go forward.

Technique 2

www.youtube.com/watch?v=--NbefyN0-M

www.youtube.com/watch?v=--NbefyN0-M

- Jul 12, 2008 - This is in response to the two videos of the guys toping off the grand, just a different technique that holds the bolt for you so you right hand is free to load. as always this is a one take video an old man told me "once you have one you'll never be without one." (the previous owner of this particular gun) all matching Springfield "except the stock and no lockbar rear sight" I'm here to tell you he is right buy one while you can great collector and even better shooter recoil is minimal for the huge 30-06 round, the biggest U.S. service round used in infantry service rifle.

CONCLUSION:

Either the BAR or the Johnson LMG could have been improved upon to be sustained-fire LMGs to give American infantry squads at least equivalency--if not the edge in battle over the heavier German MG42s.

Moreover, the Johnson rifle--and particularly its LMG--could have been developed to be a pistol grip assault rifle capable of selective-fire feed by magazines shared universally by everyone in the squad and fed by 5-round stripper clips or single cartridges in dire emergencies. We could have even improved the M1 Garand by feeding it with 20-round box magazines. Why wait for the M14?

Although the M1 Garand 0.30 rifle had long since passed from operational use with the U.S. armed forces and others, large numbers remain stockpiled in the Philippines, where their use is limited by a shortage of 0.30-06 ammunition and the necessary eight-round feeder clips. The Floro International Corporation proposed that these stocks could be modernized to M14 standard, firing standard 7.62 × 51 mm NATO ammunition from 20-round magazines. The conversion procedure includes changes to the barrel, trigger and receiver assemblies as well as the introduction of the 20-round magazine. During the conversion, the barrel is reduced in length by 40 mm.

www.floro-intl.com/garand.html

We could also have been the first Army to have assault rifles--not the Germans--had we listened to Johnson.

Today, M1 Garand stocks with pistol grips are available...I guess better late than never?

The M1 Garand should have had a pistol grip added to speed assault fire--but it's 8-round en bloc feeding system could not be expanded by drums or magazines. A whole new weapon would have had to be designed, and this manifested itself later into the superb M14 in 7.62mm x 51mm NATO which is in combat today with the U.S. military with designated marksman.

In actuality, the M14 is a magazine-fed M1 Garand and there's even a new, more compact bullpup version which can be still be stripper clip feed that's quite brilliant. Should come in a TAN finish for better weapons camouflage--and with a SureFire muzzle flash and sound suppressor--as all U.S. weapons should: combatreform.org/camie.htm

The 5.56mm M249 "SAW" has been a dismal failure as a sustained-fire LMG to suppress the enemy. Even if mechanically reliable, its puny 5.56mm cartridge does not intimidate or suppress enemies at long ranges behind urban cover and mountain rocks. It's being replaced finally by the reliable, belt-fed Mk.48 7.62mm x 51mm NATO LMG---something we have needed for over 6 decades!

Progress Needed: Muzzle Flash Suppression for LMGs

Suppressed M240B 7.62mm x 51 NATO Medium Machine Gun

Now that we are finally catching up with the Germans to where we should have been before WW2 began....it's time to face the fact that machine guns are key targets for the enemy to knock out, aiming in on their muzzle flashes. If you doubt this, read the 2008 account of the battle for Wanat village in Afghanistan:

The answer is Surefire's suppressors which at about $2, 000 each maybe are not cheap enough to give to every rifleman--but we can certainly supply them to protect $10, 000 machine guns and their gunners so we can have their battle-winning suppressive fires..Just dedicate a barrel to being connected to a suppressor...

DETAILS:

Pricing

Description

Source

SureFire, LLC

18300 Mount Baldy Circle

Fountain Valley, CA 92708

Toll Free: (800) 828-8809

Outside the US: (714) 545-9444

Fax: 9537

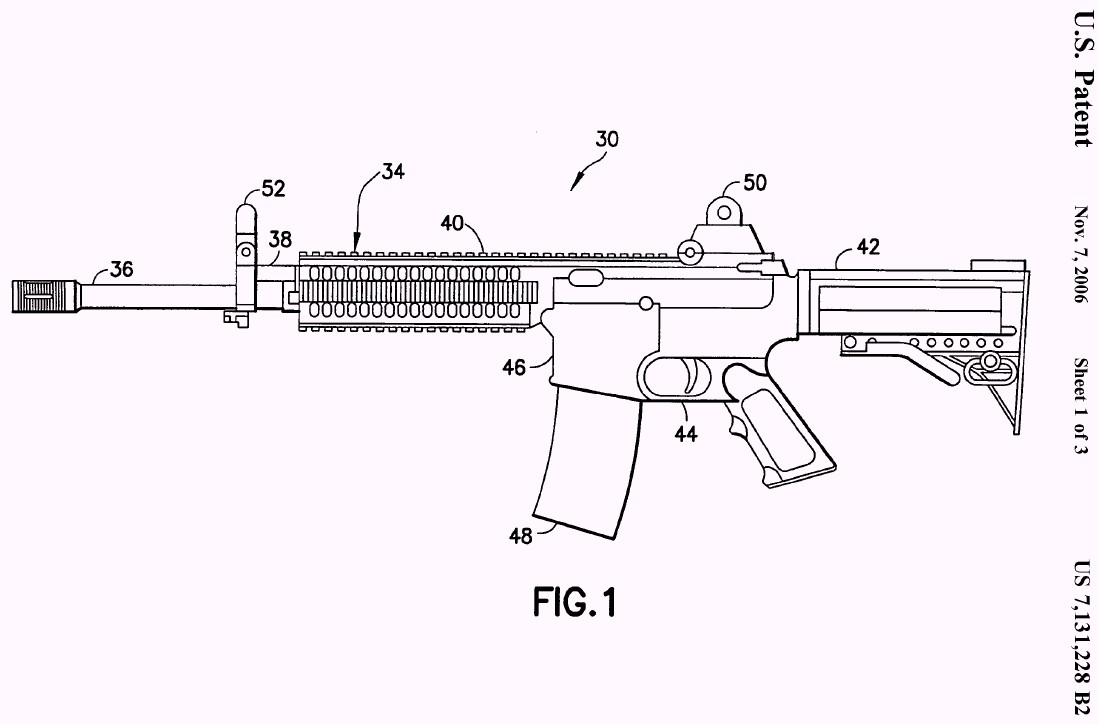

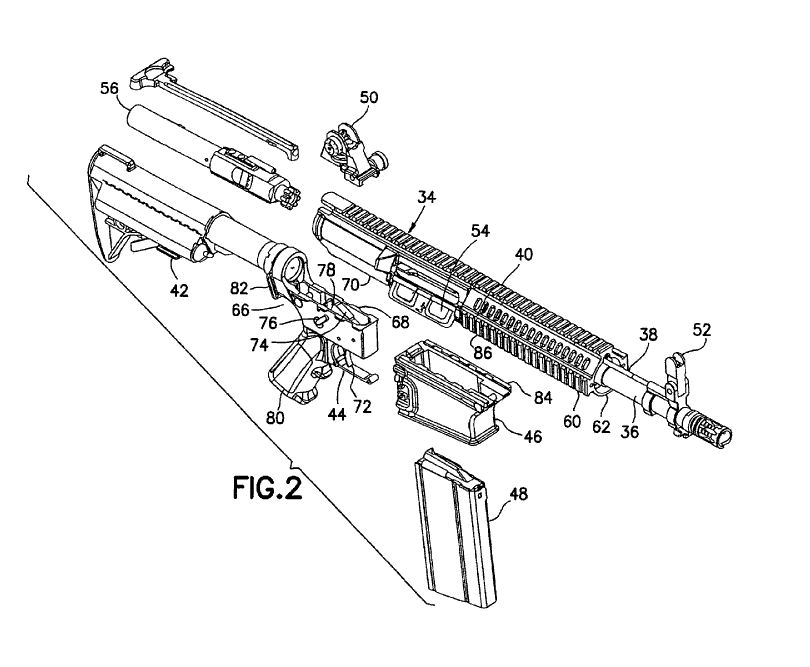

Lessons for Today: Use 7.62mm Light Machine Guns Backed by Riflemen in M16A5s in the Same Caliber

The U.S. Army Infantry's Base of Fire (BOF) or Support-by-Fire (SBF) element should engage with long-range 7.62mm x 51mm NATO fires from a belt-fed, quick-change barrel Light Machine Gun guarded by riflemen shooting the same cartridges--at the same ranges--with modular M16A5 Assault Rifles. Maneuver elements would have 5.56mm M16A5s for maximum number of rounds to fire & maneuver and do individual movement techniques (IMT). All weapons should be suppressed and come in a TAN finish for visual and sound camouflage. All barrels would be fluted to increase surface area for cooling while lightening weight.

PKM Medium Machine Gun with Fluted Barrel

M249 Light Machine Gun with Fluted Barrel

While a bullpup 7.62mm rifle like the Bulldog or Kel-Tech KFB18 would superbly shorten the length without barrel length loss, it would entail a change to the M16/M4 manual-of-arms that would be institutionally disruptive to combat efficiency during on-going conflicts if adopted force-wide. Small units that want to employ bullups could on a trial basis.

Bullpup vs. Traditional Lay-Out

To shorten the M16/M4 length we should adopt a gas piston system over the barrel to eliminate the buffer assembly and action spring in back so a sturdy-enough-for-butt-strokes, side-folding stock can be employed like on USSOCOM's FN-SCAR series. A gas piston system would solve the M16's direct gas system propensity to get dirty and jam. For more M16A5 Assault Rifle details:

"The Americans will always do the right thing . . . After they've exhausted all the alternatives."

--Prime Minister Winston Churchill

M1941 Johnson LMG History

http://anonymous-generaltopics.blogspot.com/2010/02/m1941-johnson-rifle.html

http://anonymous-generaltopics.blogspot.com/2010/02/m1941-johnson-machine-gun.html

The M1941 Johnson Light Machine Gun was an American recoil-operated light machine gun designed in the late 1930s by Melvin Johnson. It shared the same operating principle and many parts with the M1941 Johnson Rifle.

Design

The M41 light machine gun was designed by a Boston lawyer and Captain in the marine corps reserve named Melvin Johnson Jr. His goal was to build a semiautomatic rifle that would outperform the M1 Garand the Army had adopted.

By late 1937, he had designed, built, and successfully tested both a semi-automatic rifle and a prototype light machine gun (LMG). Each shared a significant number of physical characteristics and common parts, and both operated on the principle of short recoil with a rotating bolt.

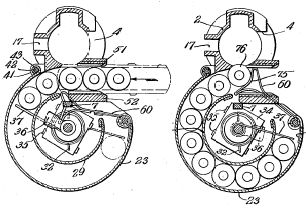

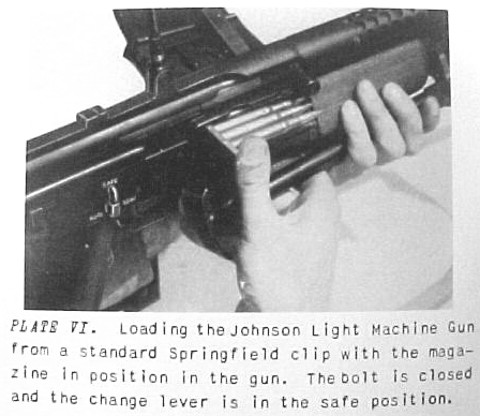

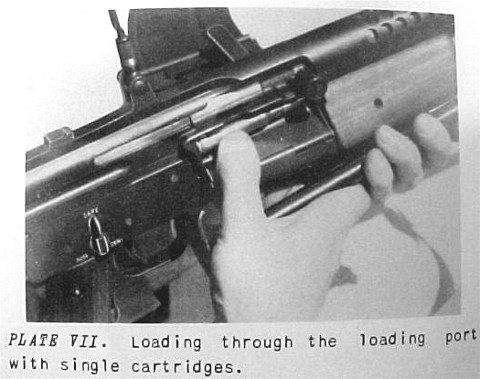

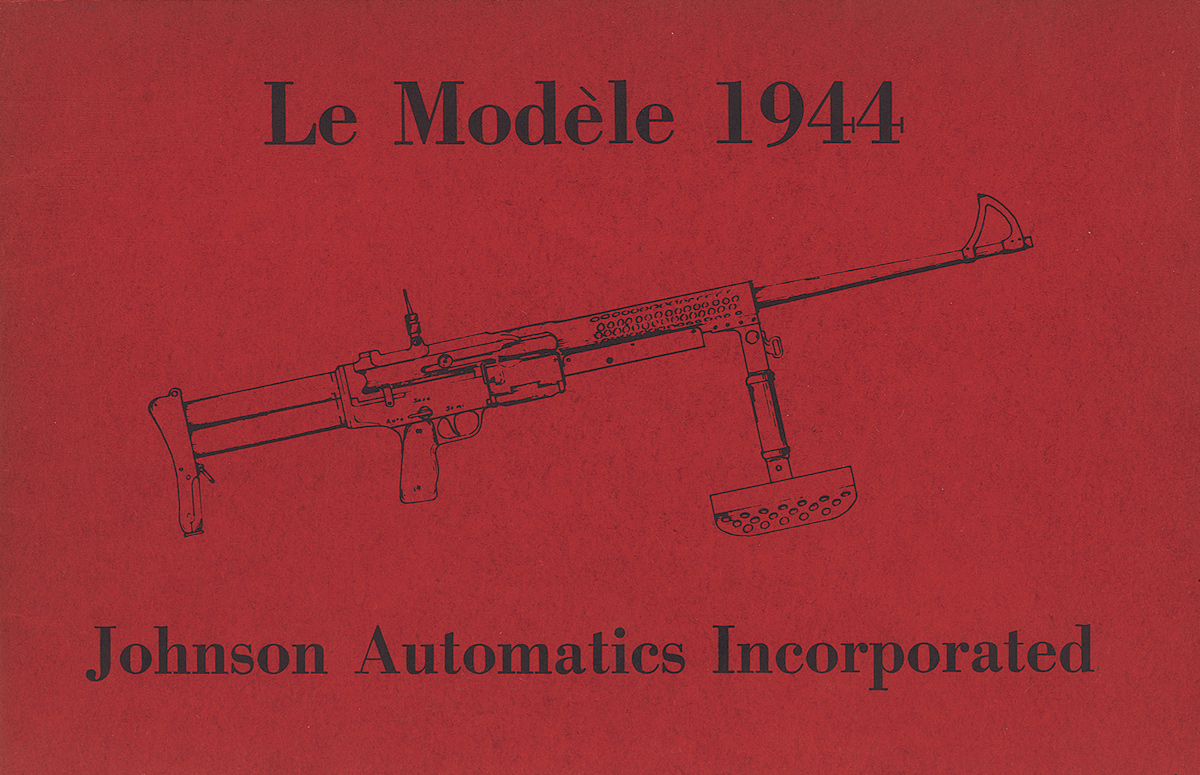

The Johnson LMG was one of the few light machine guns to operate on recoil operation and was manufactured to a high standard. The Johnson was fed from a curved, single-column magazine attached to the left side of the receiver. Additionally, the weapon could be loaded by stripper clip (charger) at the ejection port, or by rounds fed singly into the breech. The rate of fire was adjustable, from 200 to 600 rounds per minute. Two versions were built: the M1941 with a wooden stock and a bipod, and the 1944 with a tubular steel butt and a wooden monopod.

When firing, recoil forces along with the mass of the weapon's moving parts all traveled in a direct line with the shoulder of the gunner. While this in-line stock can be seen in the M16 rifle today, it was a novel idea at the time. Since recoil was directed back into the shoulder, muzzle rise was minimized. Due to this design, the sights had to be placed higher above the bore.

The Johnson LMG has many parallels with the contemporary German FG42. Both had in-line stocks, fed from the left side, and both fired from the open bolt in automatic mode and closed bolt in semi-automatic mode. Both weapons proved somewhat awkward to carry with a loaded, side-mounted magazine (especially the Johnson, which had a magazine with an unnecessarily lengthy single-column design), and this feature tended to unbalance the guns. Despite these similarities, there is no evidence that either weapon had any effect on the design of the other. Both machine guns attempted to solve similar problems, and adopted similar solutions.

Users

Johnson was successful in selling small quantities of the M41 Johnson LMG to the U.S. Army and marine corps. One notable unit that used this weapon was the U.S. Army's 1st Special Service Force, a special operations unit composed of half Canadian, half American troops (nicknamed "the Black Devil's" by the Germans). The U.S. marine corps' "Raiders" and "Paramarines" also used the Johnson LMG. Unlike the Paramarines who were hated by the USMC bureaucracy, the 1st SSF actually parachute jumped into combat in the 1944 invasion of Southern France, Operation DRAGOON.

Israeli Dror copy of the Johnson LMG was not successful in desert conditions

Shortly after the 1948 Arab-Israeli War, the predecessor of the Israel Defense Forces, Haganah, developed a close copy of the Johnson LMG, the Dror, in both .303 British and 7.92x57mm Mauser calibers. Israeli forces found the Dror prone to jam from sand and dust ingress, and the weapon was discontinued after a brief period of service. Ernesto Che Guevara notably used a Johnson repeater in the Cuban Revolution. Free Cuban Brigade 2506 used the Johnson LMG during their Bay of Pigs invasion in 1961.

Aftermath

Melvin Johnson continued to develop small arms. In 1955, he was asked to assist Fairchild/ArmaLite in (unsuccessfully) promoting Eugene Stoner's AR-10 7.62mm x 51mm NATO rifle with the U.S. Department of Defense, then with ArmaLite and Colt's Manufacturing Company as an advocate for the 5.56mm x 45mm AR-15. Armalite relied heavily on Johnson's efforts and the AR-15 used a similar bolt design to the M1941 Johnson. The AR-15 is still manufactured today in the guise of the M16 rifle and variants. One of Johnson's last postwar firearms ventures was a 5.7 mm-caliber version of the M1 Carbine, aka "the Spitfire".

Users

Canada

United States

Israel (Dror variant)

Johnson M1941 LMG

Type: Automatic rifle

Place of origin: United States

Service history

In service: 1940 to 1961

Wars: World War II, Arab/Israel war, Bay of Pigs Invasion

Production history

Designed: 1940

Produced: 1940 to 1945

Number built: 9500

Variants M1941, M1944

Specifications

Weight: 13 lbs. (5.9 kg)

Length: 42 in (1,067 mm)

Barrel length: 22 in (559 mm)

Cartridge: 7.62mm x 82mm (.30-06 Springfield)

Action: Short recoil

Rate of fire: 200 to 600 round/min variable

Muzzle velocity: 2,800 ft/s (853.6 m/s)

Feed system: 25-round, single-column box magazine

FEEDBACK!